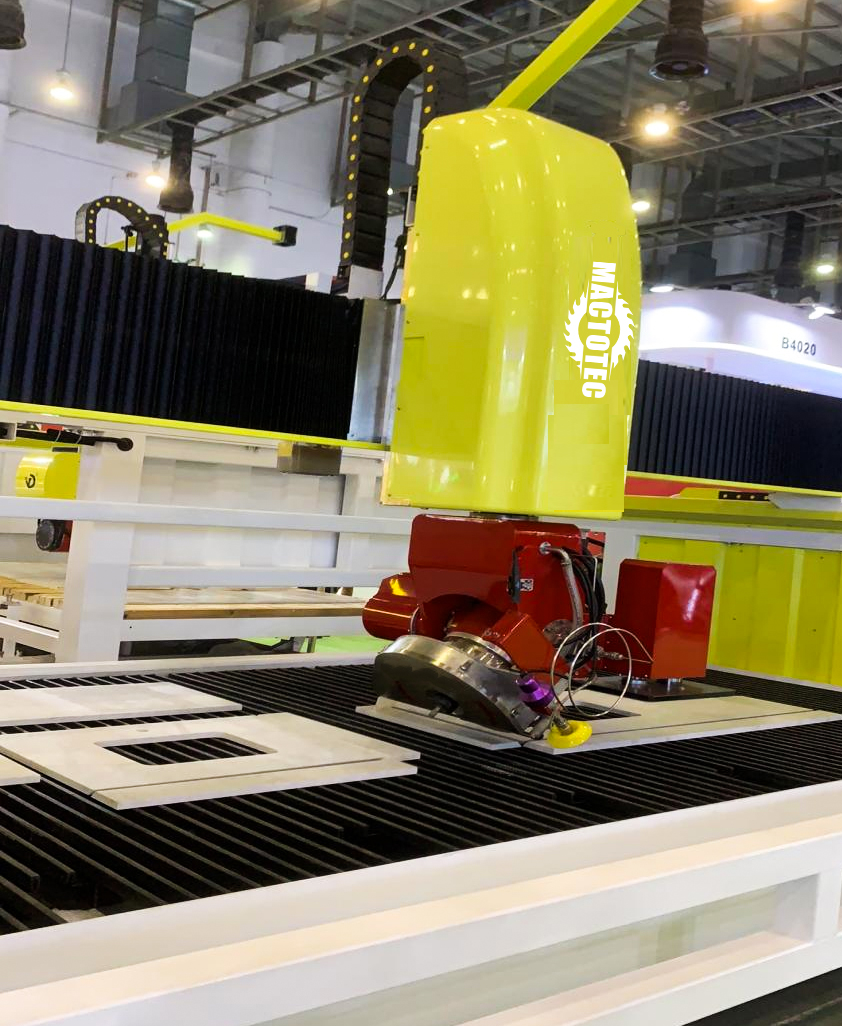

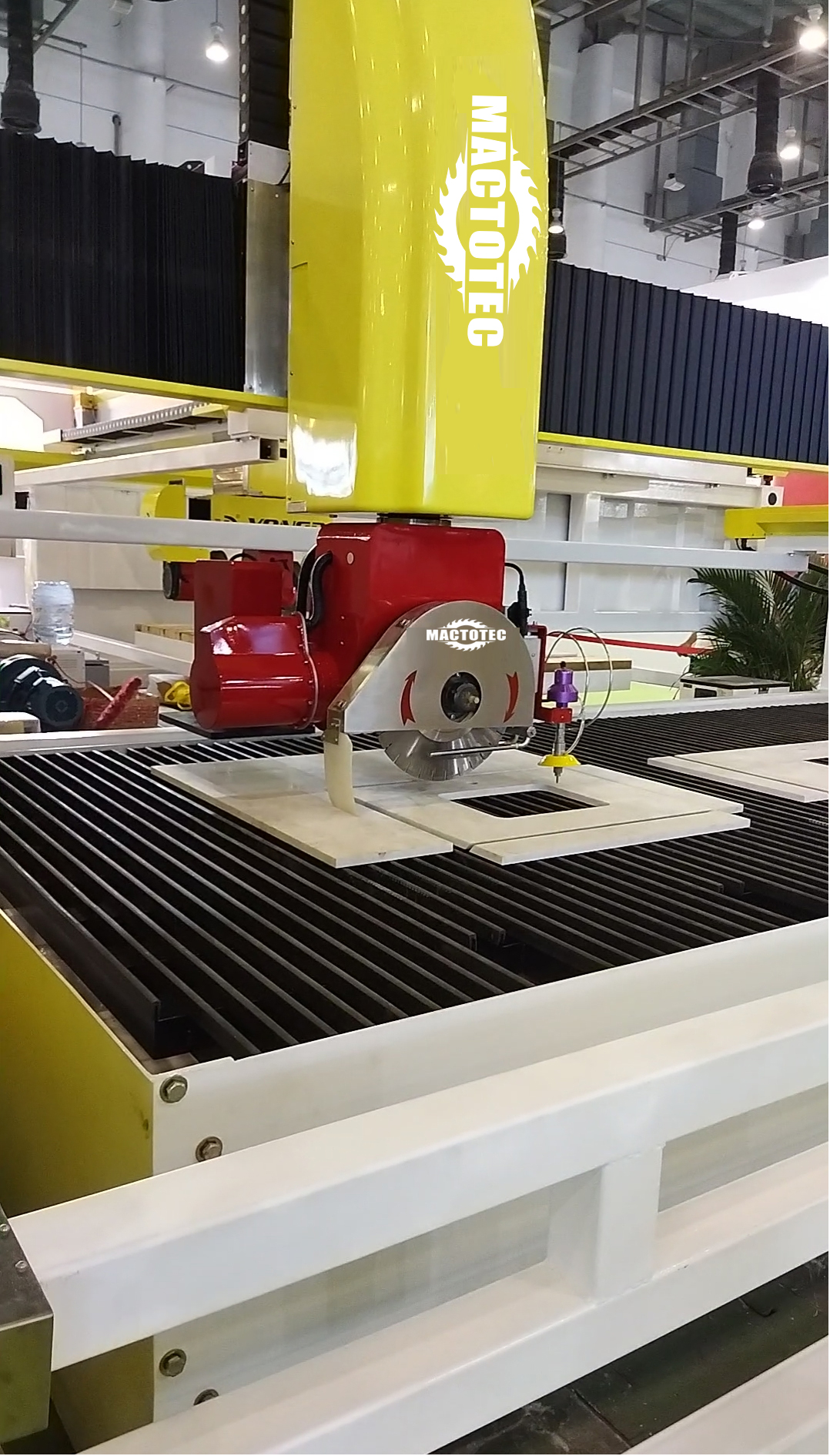

MTYD-450 5 Axis Bridge Saw +Waterjet Integrated Machine

Product Introduction

The 5 Axis Bridge Saw with Waterjet Integrate Machine is usually controlled by a computer numerical control system, which enables precise programming and automation of the cutting process. Combining Bridge Saw with Waterjet enables an efficient cutting solution. A saw provides the stability and structure needed for precise cutting, while a Waterjet is capable of making complex cuts and handling a variety of materials. The Waterjet can be used with or in conjunction with the saw blade, increasing the versatility of the cutting options.

VIDEO

1.MTYD-450 5 Axis Bridge Saw +Water Jet Integrated Machine

5 Axis Bridge Saw+Waterjet Operation Panel Video

MAIN FEATURES AND ADVANTAGES

5 Axis Bridge Saw with Waterjet is suitable for stone, countertop, cabinetry industry.

1. Combined with AC 5-axis Waterjet and 5-axis Bridge Saw function, gathering Cutting, drilling, chamfering, engraving, molding, engraving, a variety of functions in one machine.

2. Blade cutting, water jet drilling and small size curve cutting. Don’t need to move the stone from one machine to another machine, improve work efficiency, save time and cost.

3. Save operator labor costs, only need one person to operate this 5 Axis CNC Bridge Saw with Waterjet.

4. Save factory space, compared with two different machines, this combined CNC Stone Cutting Machine saves a lot of space.

5. Reduce potential problems. A combined machine is easier to maintain than two machines.

6. Good machine performance, this machine uses Italian ESA system, imported servo motor, ball screw and guide rail to keep it running well.

7. All hard materials can be processed, such as steel, glass, ceramics, stone, burning stones, plastics, etc.

TECHEICAL DATA

| Item |

Unit |

|

| Operation system |

Italy system |

|

| Cutting software |

Italy |

|

| Control method |

Servo control |

|

| Driver |

Japanese Yaskawa /Italy Assembly driver unit.

|

|

| Guideway |

Taiwan |

|

| Reducer |

Japan |

|

| Outer size: |

mm |

(Length) 6100×(width)3700×(height)3600 |

| Total Weight |

Kg |

7000 |

| Total Power |

kw |

39 (integrated machine working table)+37( supercharger )=76 |

| Working table size |

mm |

3500×2000 |

| X/Y axis stroke |

mm |

X:3700 Y:2400 |

| Z axis stroke |

mm |

500 |

| A axis stroke |

degree |

0-90°(CNC control ) |

| C axis stroke |

degree |

±185° |

| XYZ axis max. Running speed |

m/min |

X axis:30 m/min,Y axis:30 m/min, Z axis :15 m/min |

| C axis max. Rotation running speed |

r/min |

17 r/min |

| Cutting disc diameter |

mm |

Φ350-Φ450(inner holeΦ50) |

| Cutting clamp diameter |

mm |

Φ220 |

| Max. Cutting thickness |

mm |

Apply Φ450 , straight cutting max. Thickness 110mm ; while 45 °chamfering 65mm. |

| Spindle power,rpm |

22kw,1000~6000rpm |

|

| Axis Linkage |

5 axis 5 linkage |

|

| Max. Pressure for waterjet |

Mpa |

450MPa |

| Longtime running pressure |

Mpa |

350-380 MPa |

| Water jet max. Cutting angle |

60° |

|

| Supercharger inlet pressure |

Mpa |

0.2~0.4 |

| qty of vacuum cup |

2 |

|

| Sucker lifting weight |

kg |

≤300 |

| Air pressure |

Mpa |

0.7 |

| Voltage |

V/Hz |

AC 380V / 50Hz |

| Water consumption |

L/min |

20-30 L/min |

| Optional function |

Vacuum cups,camera , height measurement, and cutting disc alignment

|