MTSY Series Multi-wire Saw Machine

INTRODUCTION

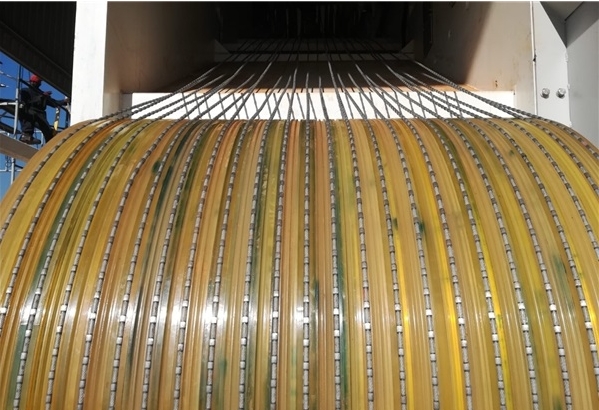

There are a variety of models to choose according to different block size, which provides the possibility for stone enterprises to process large stone plates, and broadens the application range of multi-wire saw machine. This machine is composed of the following main components: transmission system, tensioning system, truck moving system, speed regulation and pressure regulation system, water spraying system, lubrication system.

The our Multi-wire Saw Machine abandons the traditional linear roller system and adopts precision linear sliding rail to ensure the stable operation of the column linear sliding rail in the process of processing. The international new digital control technology is used to ensure the smooth operation of the diamond wire saw machine. Self-developed tensioning system, PLC digital control system, modular combination of components, so that the machine has the advantages of simple structure, easy operation, small footprint, high efficiency, clean and environmental protection. This machine is widely used for granite, artificial stone plate processing filed.

Working Site Video

MAIN FEATURES AND ADVANTAGES

1.Multi-wire Saw Machine is widely used in the processing of stone blocks in factories. It is equipped with a combination of diamond wire to cut large stone blocks to achieve efficient production of large slabs.

2.This wire saw machine has high cutting efficiency and strong stability.

3.Human-machine intelligent system design, easy to operate, and equipped with complete production safety protection functions.

4.The rigidity of the structure and the isosceles triangular geometry with wire just 20 meters long, guarantee lower wire vibration while cutting, leading to higher cutting accuracy and longer service of rubber profiles.

5.Low maintenance cost and good technical service

Technical Data

|

Model |

Unit |

MTSY-12 |

MTSY-32 |

MTSY-50 |

MTSY-74 |

|

Wire Diameter |

mm |

7.3 |

7.3 |

7.3 |

7.3 |

|

Slab Thickness |

mm |

20/30/50/70 |

20/30/50/70 |

20/30/50/70 |

20/30/50/70 |

|

Wire Quantities |

pc |

12/9/6/5 |

32/24/16/12/11 |

50/38/25 |

74/56/37 |

|

Wire Length |

mm |

20 |

20 |

20 |

20 |

|

Max. Cut Height |

mm |

2200 |

2200 |

2200 |

2200 |

|

Max. Cut Length |

mm |

3400 |

3400 |

3400 |

3400 |

|

Line Speed |

M/s |

0-40 |

0-40 |

0-40 |

0-40 |

|

Tension |

kgf |

150-280 |

150-280 |

150-280 |

150-280 |

|

Cooling Water |

L/min |

180 |

500 |

700 |

1100 |

|

Machine Size |

m |

10*2.5*6.5 |

10*4*6.5 |

10*5*6.5 |

10*5.5*6.5 |

|

Machine Weight |

t |

20 |

38 |

52 |

70 |

|

Main Motor Power |

kw |

55 |

132 |

250 |

280 |

|

Total Power |

kw |

65 |

145 |

273 |

304 |