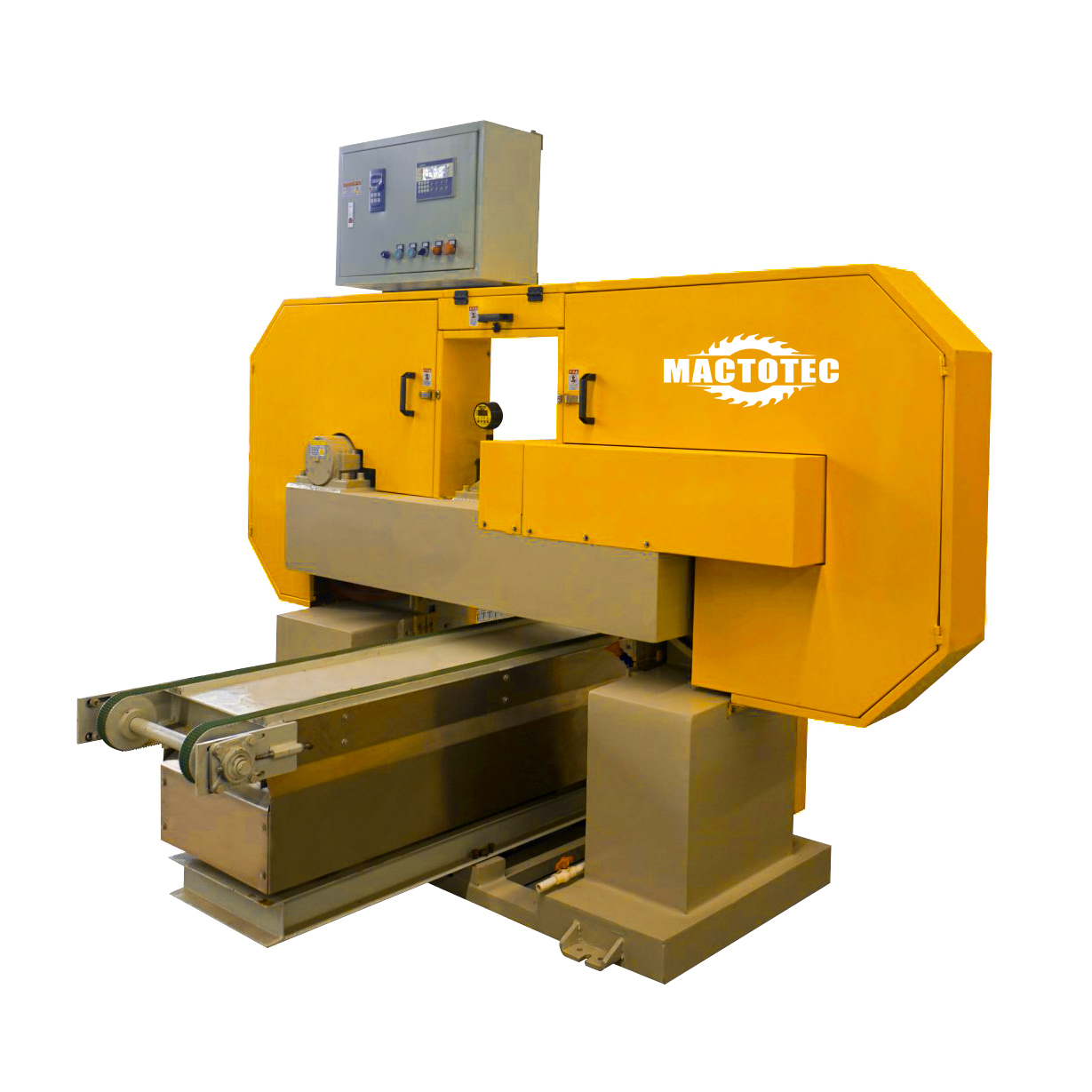

MTR-1200 Bridge Type Middle Block Cutting Machine

INTRODUCTION

This machine adopts microcomputer control, plus wireless remote control, making man-machine dialogue flexible and free.

The main control components are made of international brand components, the beam and the head are made of large, heavy structure, oil-immersed double V beam track, equipped with high-power cutting

The cutting main motor, the transverse cutting tool adopts stepless frequency conversion and flexible speed regulation, the longitudinal cutter adopts the double mountain guide rail and the high precision encoder counting to ensure the machine smooth and stable accuracy.

MAIN FEATURES AND ADVANTAGES

1.The bridge saw is a highly automatic machine well built to perform various tasks in marble and granite processing. It is ideal in cutting tombstone, building stone and big size slabs etc.

2.Adopts microcomputer control system and human-machine interface, combined with ultra-high precision rotary encoder to locate and infrared device, uses inverter to control left-right feeding, adjusts the speed according to the stone material.

3.Two bridge tracks are installed on metal shoulders. On top of each bridge track is gear near guide way system to having the bridge smooth movement and precise positioning. Oil-bath bridge tracks are covered to be protected from dust and water spray.

4.The bridge has been built in large thickness normalized cast iron. Cast iron gives the bridge high level rigidity, prevents the bridge from shape deformation.

5.Two V-shaped tracks are machined on the bridge top with small clearance to guide disc holder move in straight line, result in the disc do straight cutting. This disc holder track is also covered and oil-bath.

6.Disc lifting/lowering movement is powered by hydraulic cylinders and guided by four surface chrome-plated steel columns.

7.Limit switches are automatically limiting the disc moving range during stone cutting.

8.Cutting parameters can be put into the machine by control panel and then the bridge saw make automatic cutting owing to its PLC control system.

Technical Data:

|

Model |

MTR-1200 |

|

|

Blade Diameter |

mm |

Ф600-1200 |

|

Blade Up/down Stroke |

mm |

820 |

|

Main Motor Power |

kw |

22 |

|

Total Power |

kw |

27.2 |

|

Water Consumption |

m3/h |

4 |

|

Worktable Size(Max. Cutting Size) |

mm |

3000*2000 |

|

Worktable Rotation Angle |

° |

0-90 |

|

Dimension(L*W*H) |

mm |

6400*4800*4400 |

|

Weight |

kg |

6100 |