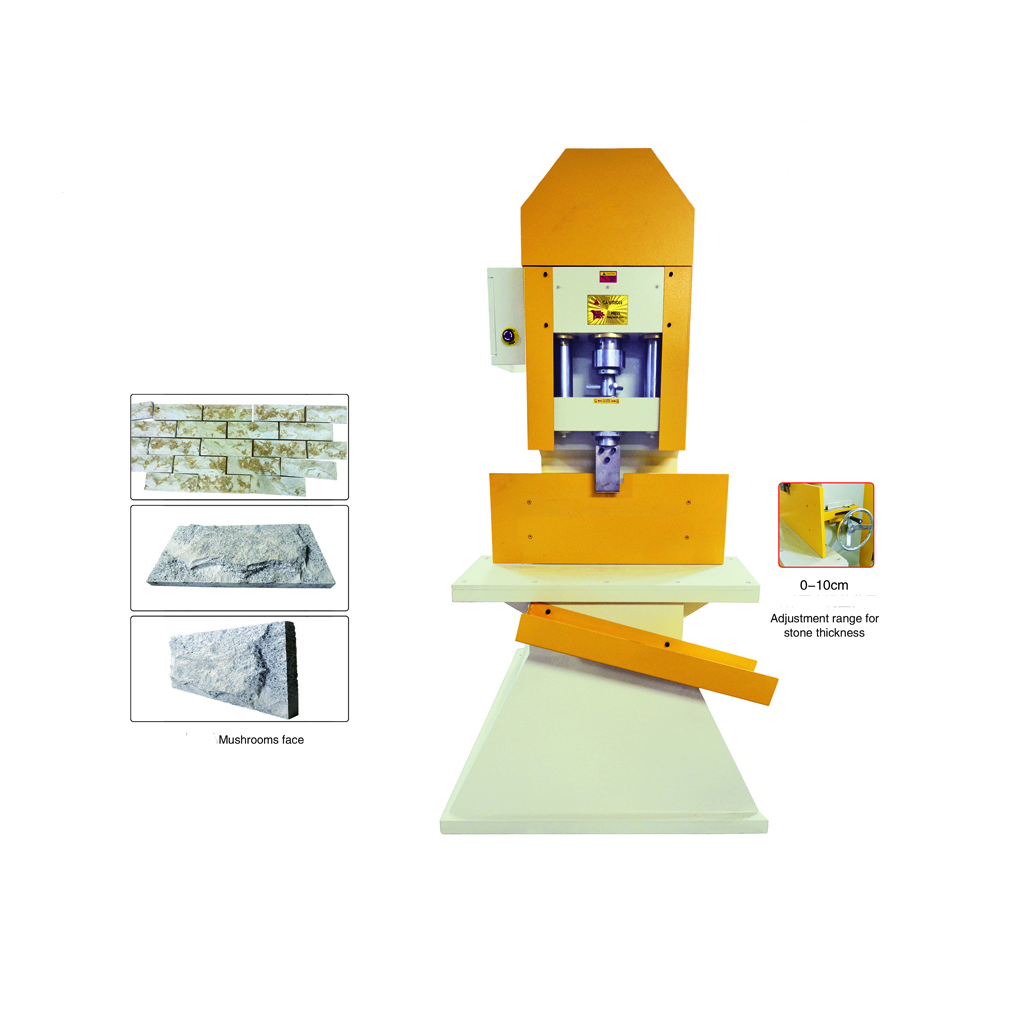

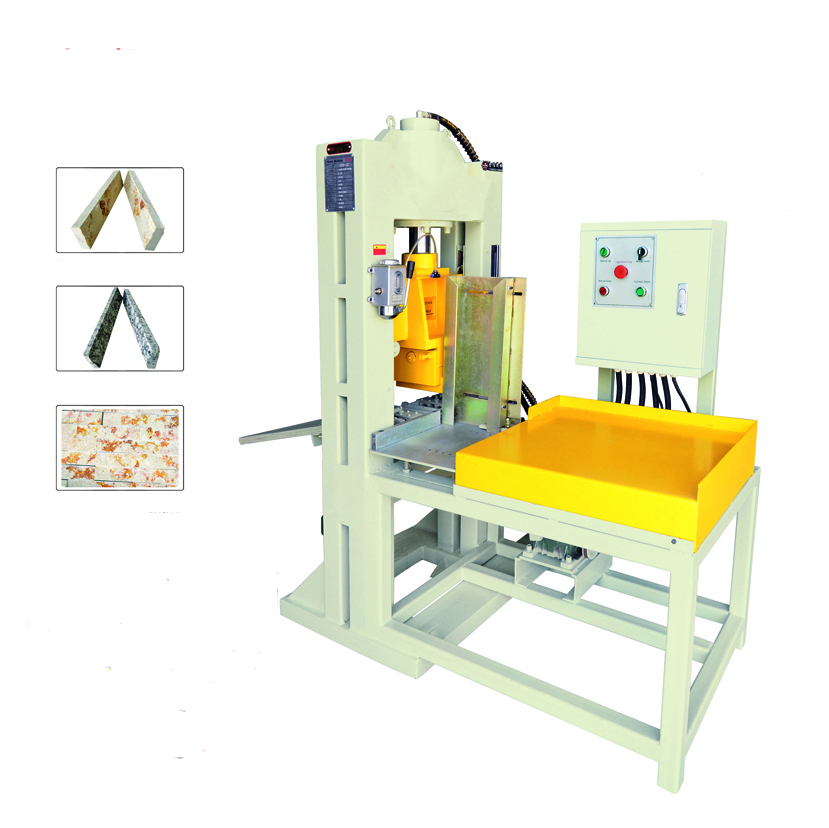

MT-S74 Mushroom Face Stone Splitting Machine

INTRODUCTION

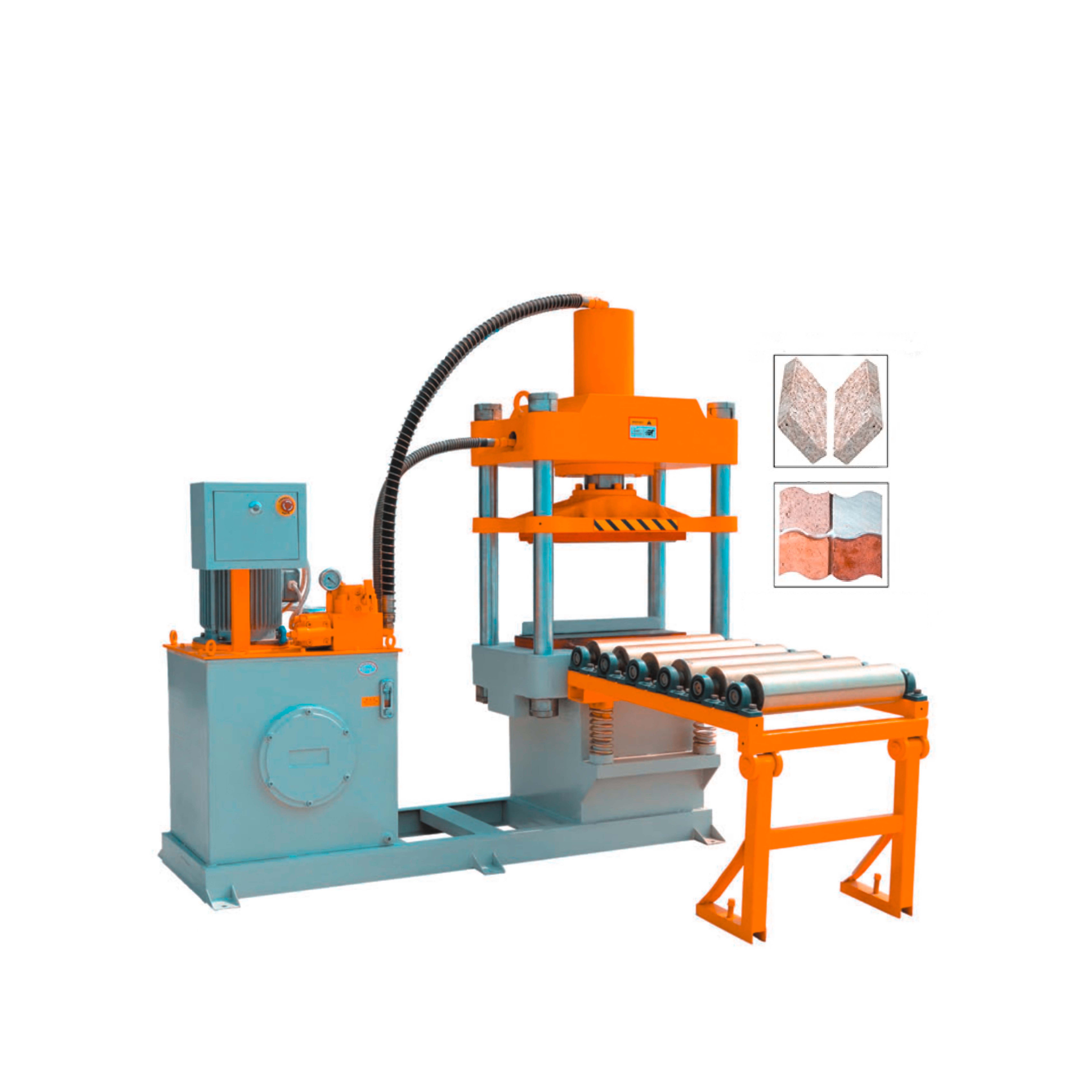

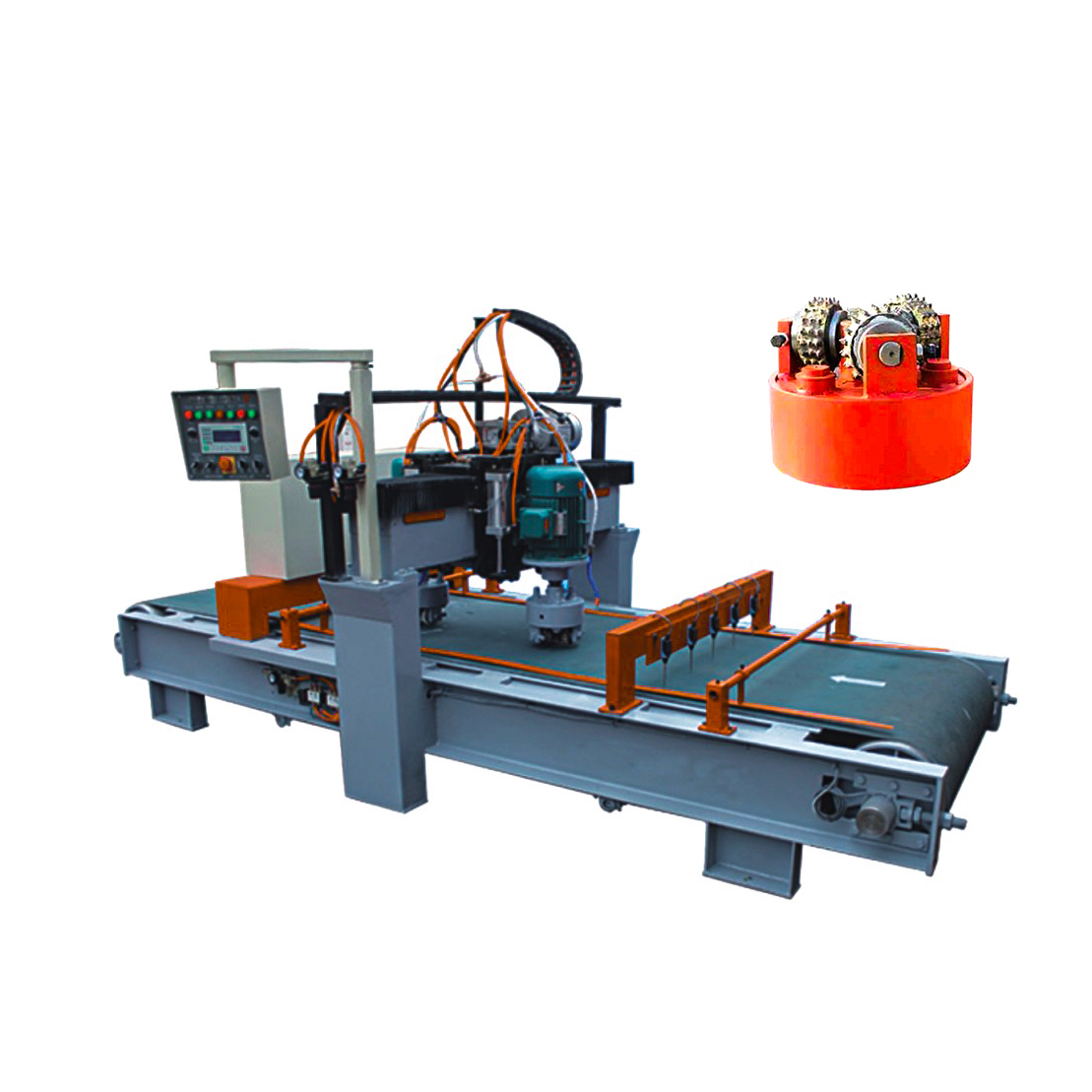

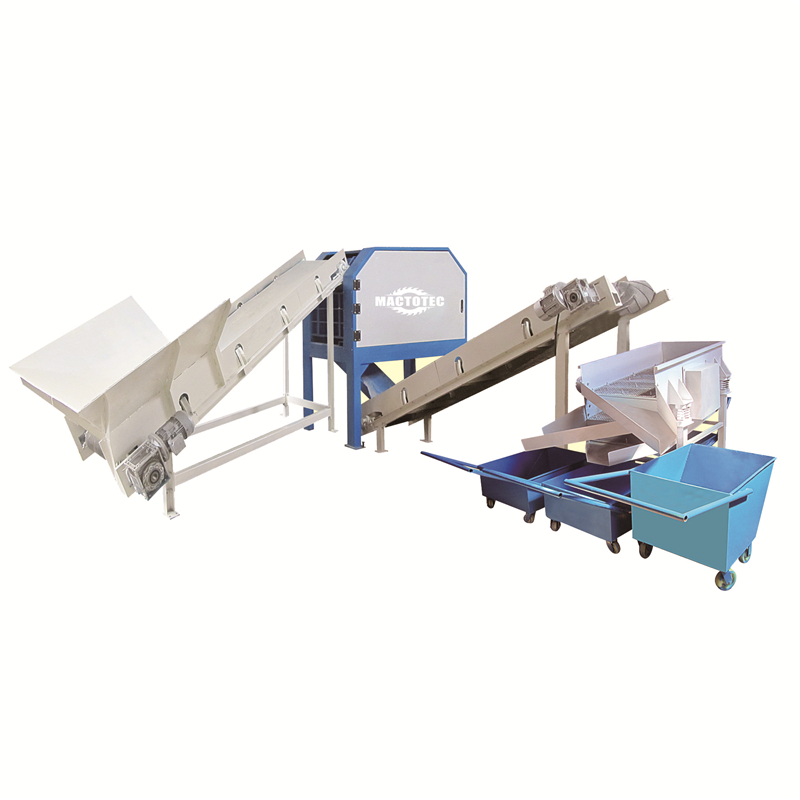

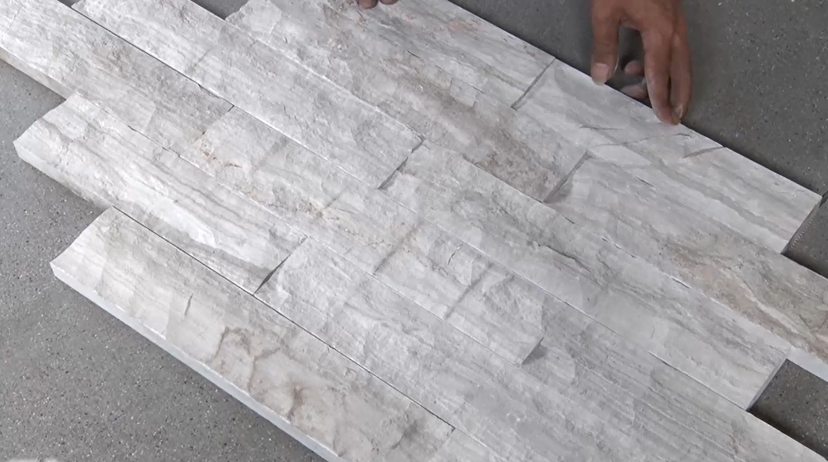

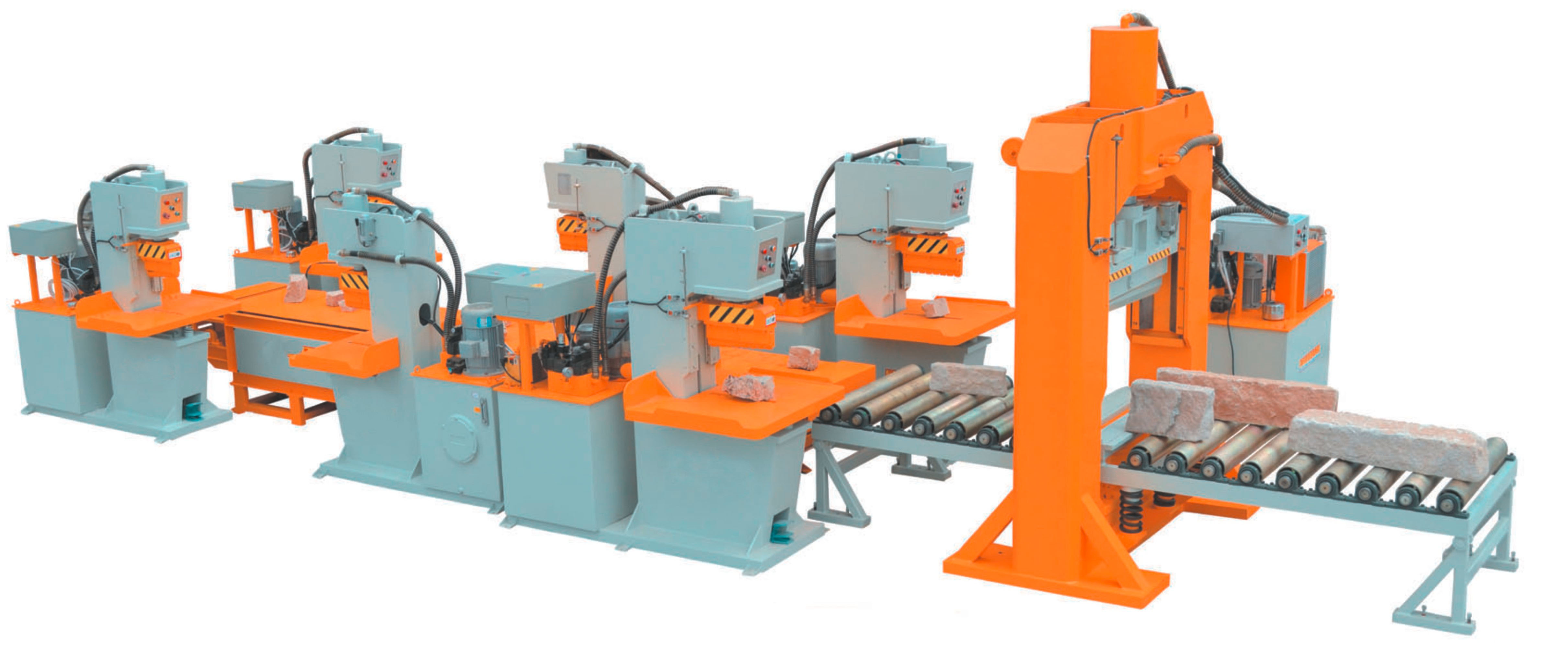

Splitting machines are extremely wonderful to produce Paving stones, tiles for paving and cladding, decorative Wall stones and Kerb stones, etc. It can process granite, basalt, quartz, limestone, sandstone, porphyry and many other types of natural stone. Machine with features of high reliability and easy handling, every splitting machine can be integrated designed in a production line to satisfy your specific needs. needs.

Model MT-S74 mainly designed for mushroom face splitting. Applicable for residential landscape , house buildings and commercial buildings, etc.

Model MT-S74 splitting machine suitable for 5-30cm height X5-60cm length materials processing.

The machine hydraulic system uses top grades hydraulic components which with stable performance, no oil leakage, low noise and long service life. you can achieve fantastic production performance and considerable reduction in operating costs.

Machine,generate hydraulic power to split the stone down in a spot. gives great power and the ability to split material of even very hard stone., greatly improve production efficiency and produce unbeatable splitting quality.

Heads Fast lift up and down movement makes working efficiency greatly improved . splitting speed 2 times per second.

Operation of machine is easy. starting the machine and place material to good position which under blade. the splitting head will automatically move up and down repeatedly to split the stone so as to make mushroom face.

Its low weight allows it to be used in multiple sites in operation or on a construction site.

Machine build by strong cast iron and uses high quality parts, stability guaranteed during continuous works. Splitting blade is made from super hard alloy with advantages of long lifetime and not easily deformed or breakdown. When the cutting blade is consumed, just take off the fastener to replace with new one easily..

Technical data

| Model |

|

MT-S74 |

| Power |

kw |

1.5 |

| Voltage |

v |

380 |

| Frequency |

hz |

50 |

| Segment width |

mm |

80 |

| Pressure |

t |

40 |

| Max working height |

mm |

50-300 |

| Max working length |

mm |

50-600 |

| Blade feeding speed |

times/s |

2 |

| Dimension |

mm |

1000x900x2110 |

| Weight |

kg |

950 |