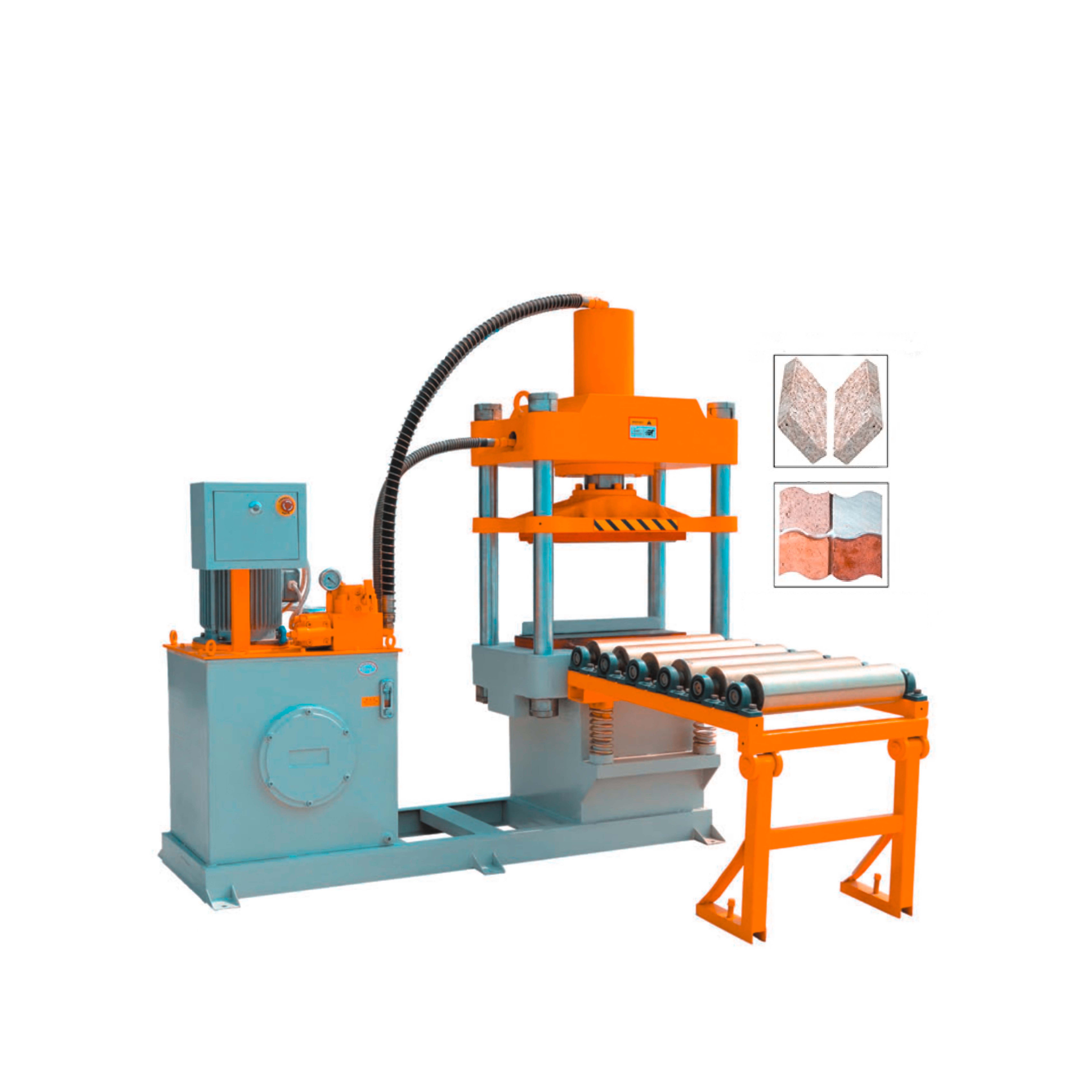

MT-S72/MT-S85 Stone Splitting Machine

INTRODUCTION

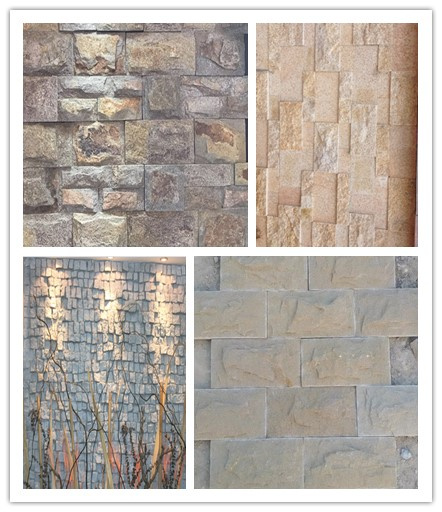

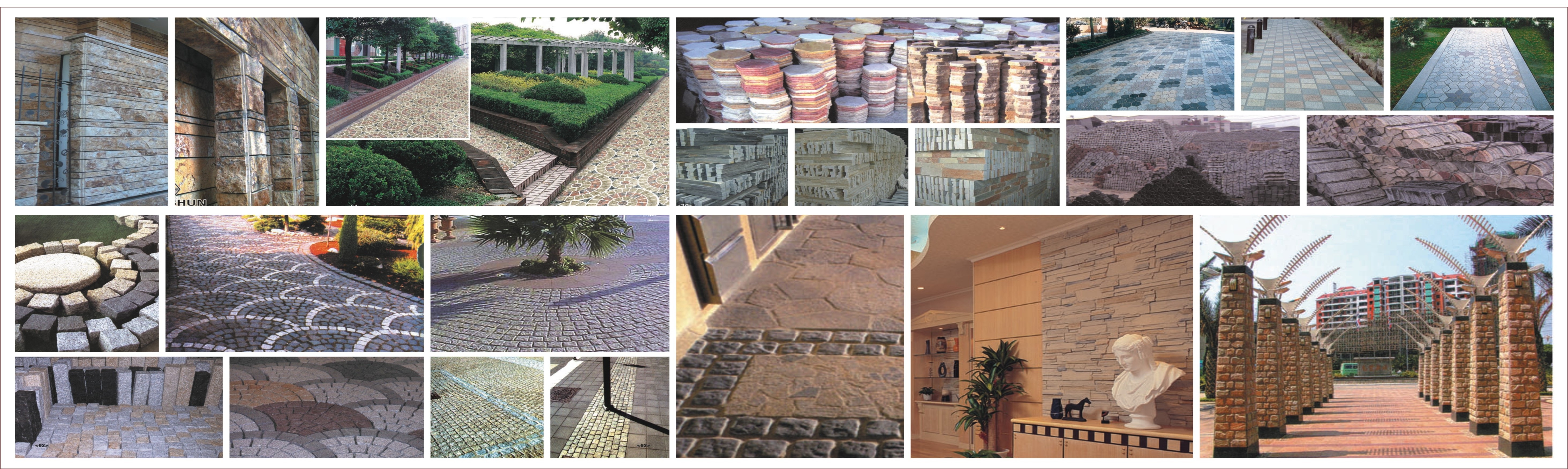

Using this splitting machines you could produce a wide range of products such as Cobble stones, Paving stones, tiles for paving and cladding, decorative Wall stones and Kerb stones, etc. It can split granite, basalt, gneiss, limestone, sandstone, porphyry and many other types of natural stone.

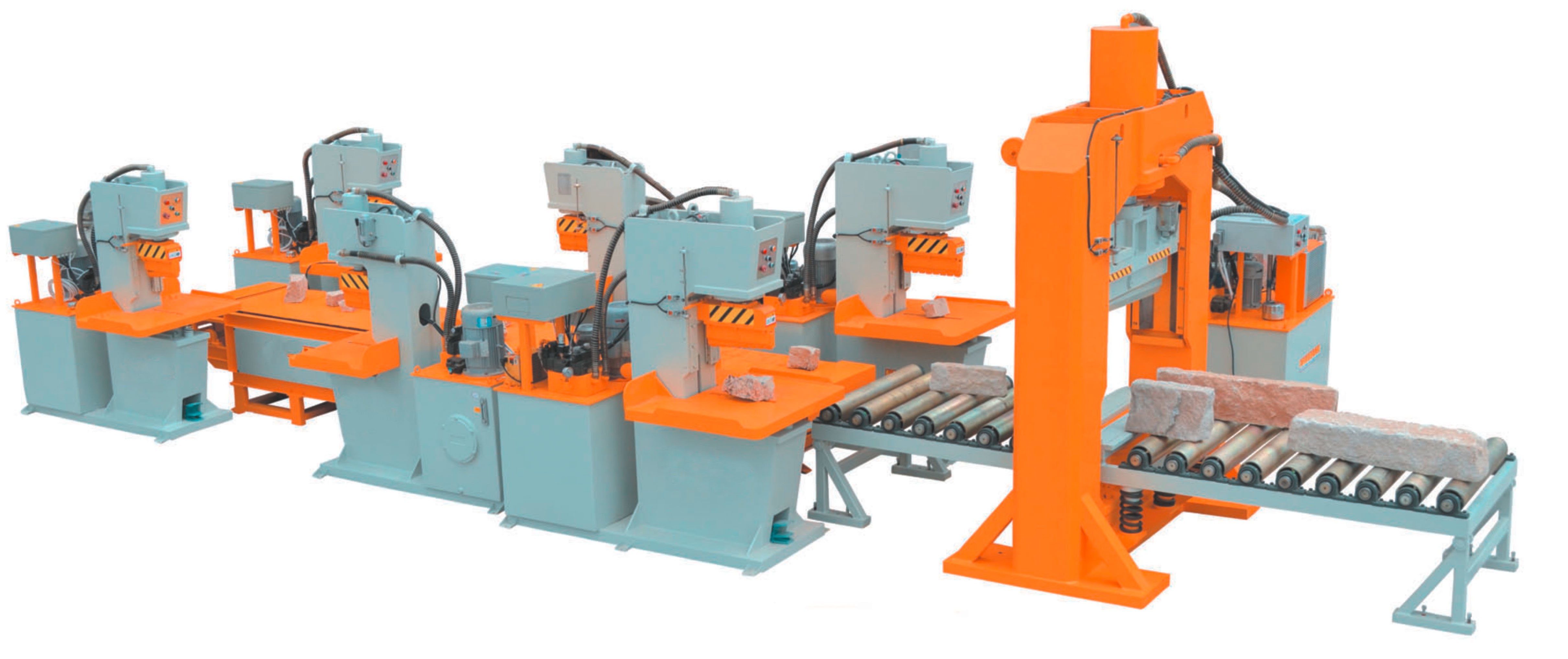

Machine characterized by high reliability and easy handling, every splitting machine can be integrated designed in a production line especially to your needs.

Model MT-S72 and MT-S85 can be replaced with 3 types of blades tools, multi functional to get natural surface, mushroom surface and polygonal kerb stones.

With MT-S72 splitting machine you can works for maximum 20cm height X40cm length materials, with output about 12㎡ per hour.

With MT-S85 splitting machine you can works for maximum 30cm height X60cm length materials, with output about 30㎡ per hour.

The hydraulic system of machine mainly uses top grades hydraulic components which with stable performance, no oil leakage, low noise and long service life. you can achieve unbeatable production performance and significant reduction in operating costs.

Intelligent gear cutting head, can adjust itself according to the condition of the stone face, and then, generate hydraulic power to split the stone down in a spot. which greatly improve production efficiency. Heat-treated and hardened high-carbon steel chisels produce superior splitting quality every time.

Fast lift up and down movement makes working efficiency greatly improved .

The stone splitting machine is equipped with a special hydraulic system. It gives great power and the ability to split material of even very hard stone.

Floating knives, which adapt to the stone shape, help enhance the quality of the split surface.

Its low weight allows it to be used in multiple sites in operation or on a construction site.

Made of strong cast iron and high quality parts ensuring stability during working.

TECHNICAL DATA

| Model |

|

MT-S72 |

MT-S85 |

| Power |

kw |

4 |

4 |

| Voltage |

v |

380 |

380 |

| Frequency |

hz |

50 |

50 |

| Flow Rate |

L/m |

14 |

17 |

| Pressure |

t |

40 |

50 |

| Max working height |

mm |

200 |

300 |

| Max working length |

mm |

400 |

600 |

| Blade feeding speed |

mm/s |

30 |

30 |

| Output/Hour |

㎡/h |

12 |

20 |

| Applicable Moulds |

|

Splitting Mould Stamping Mould |

Splitting Mould Stamping Mould |

| Hydraulic Oil Grade |

|

46# |

46# |

| Oil Tank Capacity |

kg |

66 |

74 |

| Dimension |

mm |

620x620x1770 |

620*620*2050 |

| Weight |

kg |

800 |

950 |