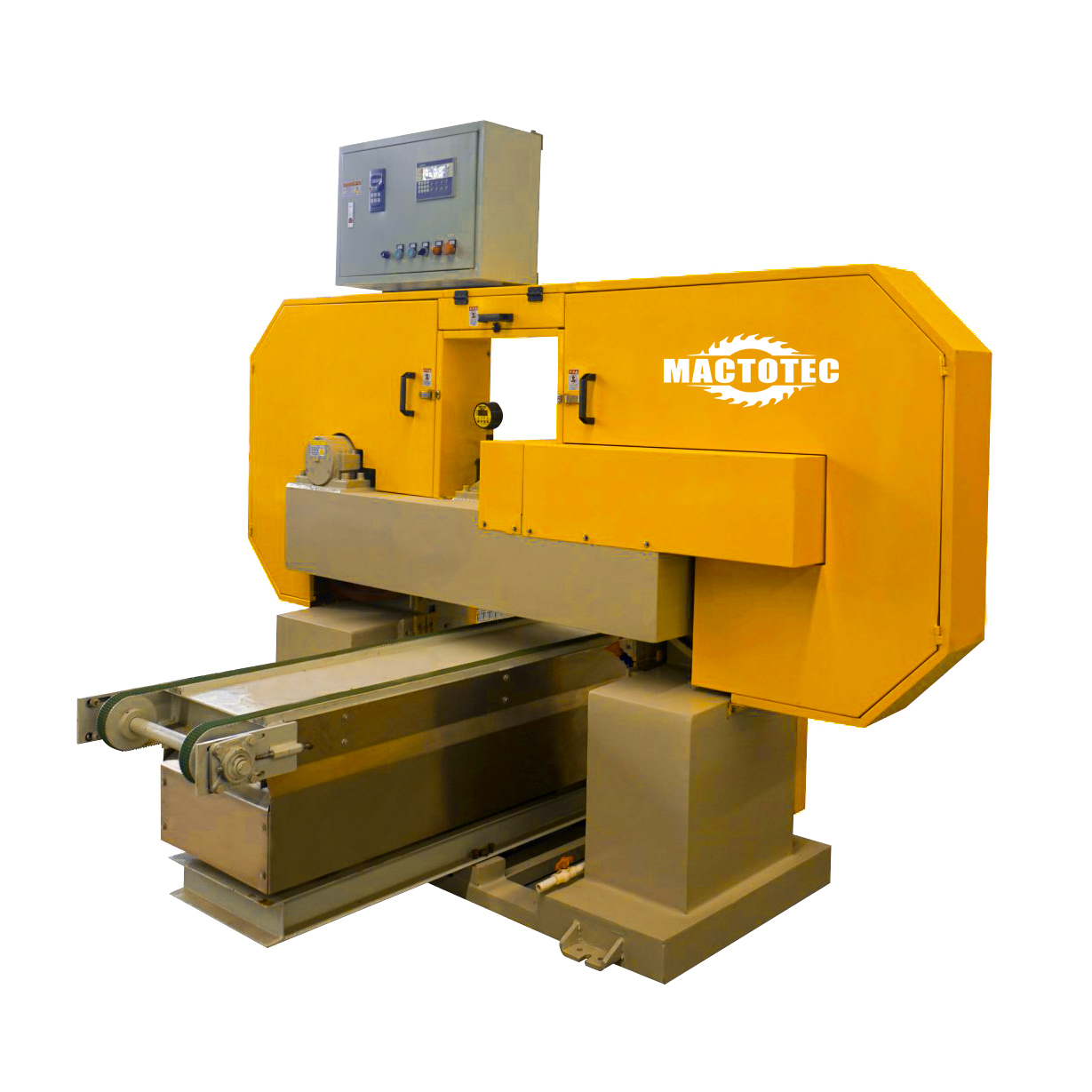

High Quality Full-Automatic Stone Surface Bush Hammer Machine - STONE BUSH HAMMER MACHINE – MACTOTEC

High Quality Full-Automatic Stone Surface Bush Hammer Machine - STONE BUSH HAMMER MACHINE – MACTOTEC Detail:

INTRODUCTION

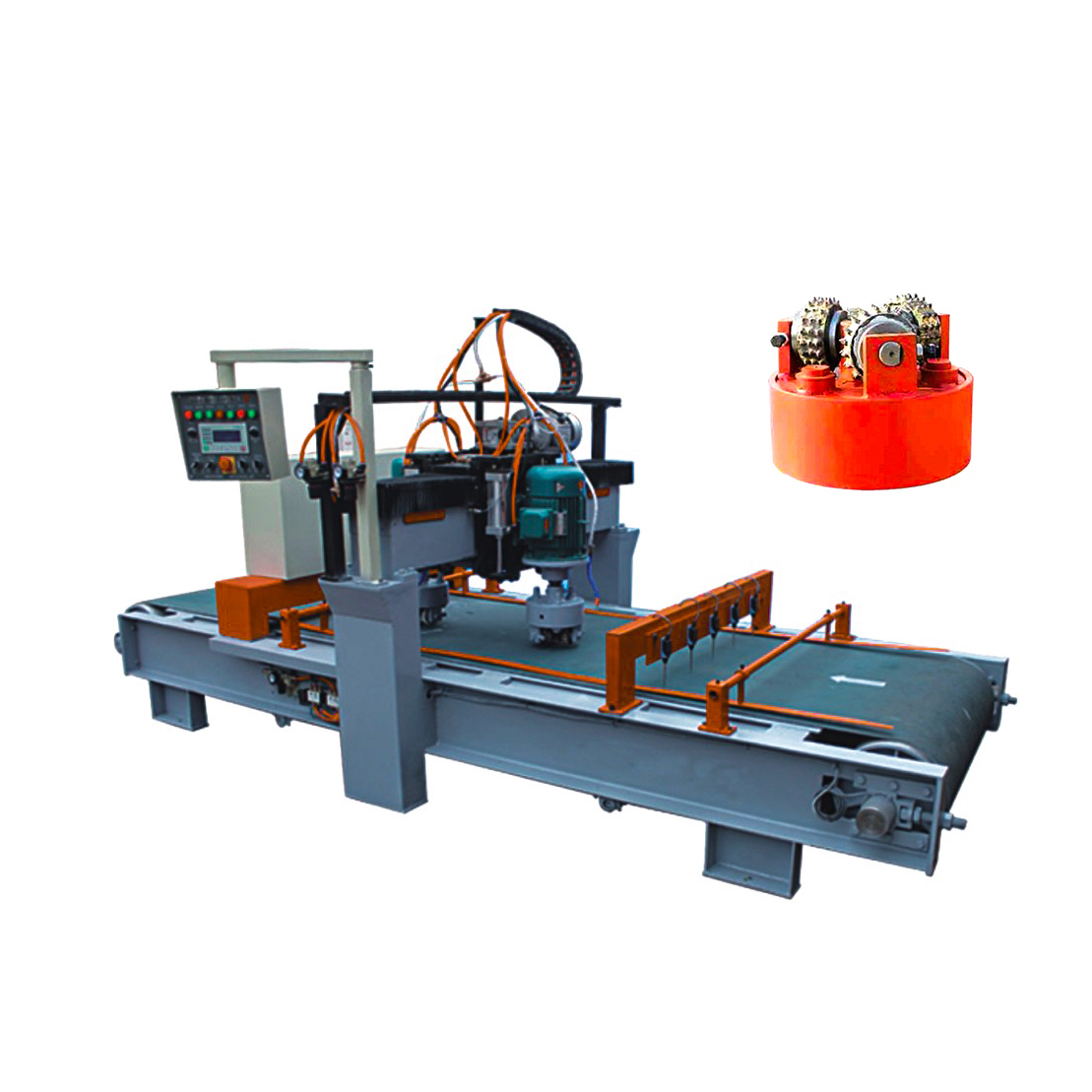

This machine applies to the surface bush hammer processing for granite and marble. the bush hammer slabs are widely used on square or Pedestrian.

This machine is designed in very reasonable structure and easy operation, you will understand all the functions and operate it well in very short time.

Stone bush hammer machine adopt PLC control, continuous conveyor belt transmission as the same working mode as automatic polishing machine , makes it very high processing efficiency. 2 heads model processing capacity about 30-50㎡/h, 4 heads model processing capacity about 60-80㎡/h/.

Bush hammer machine for granite and marble with 2 or 4 heads and full automatic control system to guarantee the slabs to be processed into bush hammered surface in one time. The final surface after processed are natural, well-balanced and good looking.

The transmission speed of conveyor belt and swing frequency of bush hammer heads can be flexible adjusted as per your actual processing demand and stone characteristics, in this case can get better quality final products.

Each bush hammer heads can works independently, take 4 heads model for example, if you would like only 2 bush hammers work, you can only start the power of 2 heads and close the other 2.

The feeding end equipped with computer scanning device, so the bush hammer heads can automatically lift to avoid collision between heads and slabs.

The working mode can be switched between the manual and automatic mode, heads up and down can be controlled flexibly.

When processing antique surface, the NO. 3 and NO.4 heads can be changed with polishing brush, so that the NO. 1 and 2 grinding heads process bush hammer surface and NO. 3 and NO.4 heads process polishing work so as to finish the whole process successfully at one time. It effectively reduces cost and achieves higher efficiency.

Technical Data

| Model |

MTFZ-2-1000 |

MTFZ-4-1000 |

MTFZ-4-2000 |

|

| Heads Quantity |

pc |

2 |

4 |

4 |

| Main Motor Power |

kw |

3 |

3 |

3 |

| Walking Motor Power |

kw |

1.5 |

1.5 |

1.5 |

| Total Power |

kw |

8.6 |

16.5 |

17.2 |

| Main Motor Speed |

r/min |

980 |

960 |

960 |

| Power Supply |

v/hz |

380/50 |

380/50 |

380/50 |

| Max. Processing Width |

mm |

1000 |

1000 |

2000 |

| Overall Dimensions(L*W*H) |

mm |

3400*2150*1800 |

4350X2250X1800 |

4300X2800X1600 |

| Weight |

kg |

2000 |

2680 |

3000 |

| Capacity |

(M2/H) |

30~50 |

60-80 |

60-80 |

Product detail pictures:

Related Product Guide:

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for High Quality Full-Automatic Stone Surface Bush Hammer Machine - STONE BUSH HAMMER MACHINE – MACTOTEC , The product will supply to all over the world, such as: Romania, Durban, Ghana, We warmly welcome your patronage and will serve our clients both at home and abroad with products and solutions of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

In China, we have many partners, this company is satisfying to us, reliable quality and good credit, it is worth appreciation.