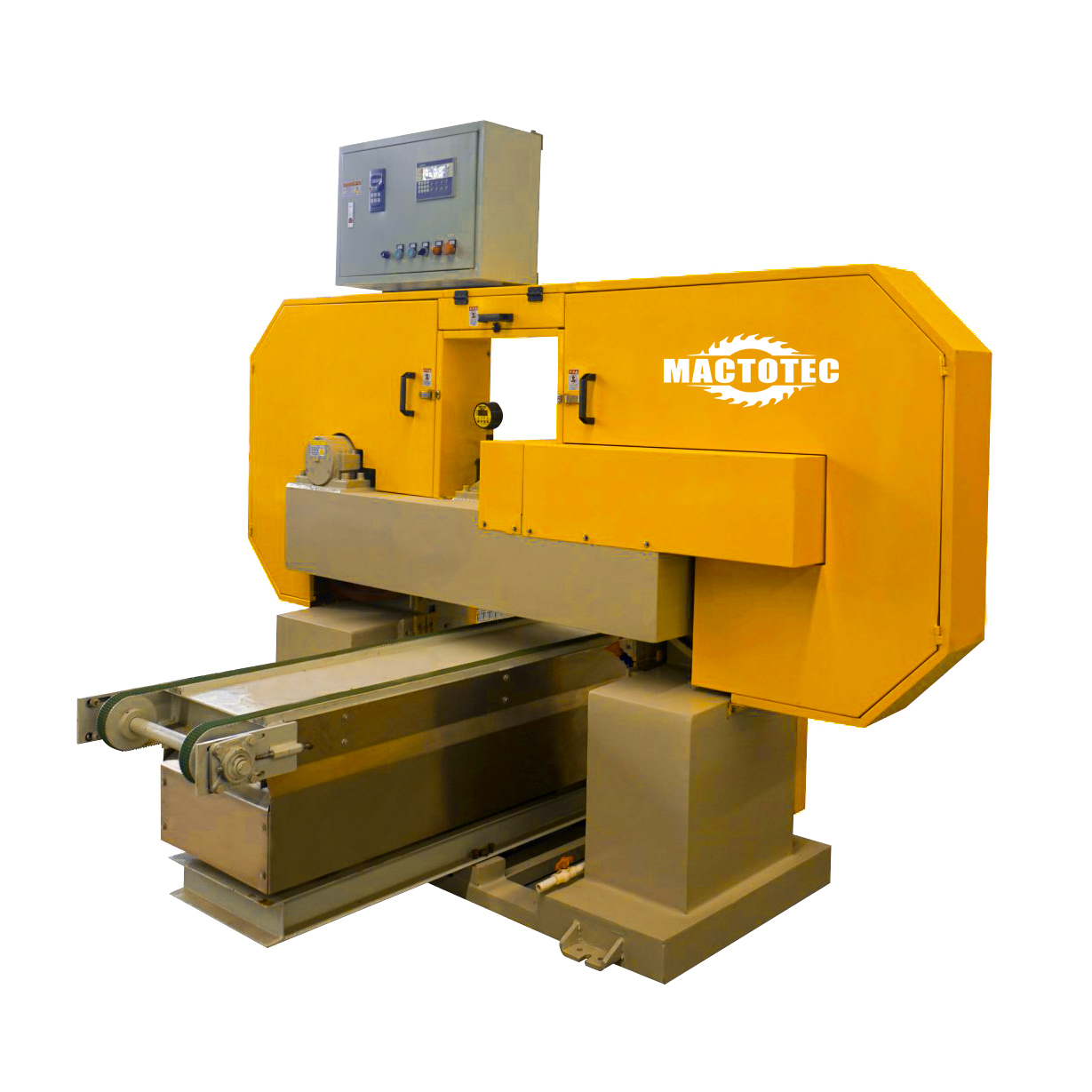

High Quality Block Cutting Machine - 4 AXIS BRIDGE CUTTING MACHINE – MACTOTEC

High Quality Block Cutting Machine - 4 AXIS BRIDGE CUTTING MACHINE – MACTOTEC Detail:

INTRODUCTION

This machine is mainly used for special-shaped edge cutting on marble, artificial stone, granite , ceramic tile,etc.

This saw machine common used saw blade diameter is 350mm, it can cut 5cm thickness stone material. the max saw blade diameter can be 400mm.

PLC control system, touch-type interface, modular parameter input, equipped with wireless remote control, this machine operation is unimaginable easy, there are different shapes modules displayed on screen , you just need choose the shape module you need to cut, click it in and input the size information as per your actual processing requirement, machine will finish cut automatically.

The cutting head can rotate 0-360°freely,and head tilt among 0-45°, So it can cut slabs in any degree and get all kind of shapes such as Automatic cutting of slabs/tiles + four-sided chamfering + grid + stove top + basin hole + polygon + trapezoid + rhombus + sector + outer circle edge + oval edge + horse belly edge + line profiling for optional ······

Table tilt 0-85°automatically which greatly reduce labor intensity and makes slab loading and unloading more efficiency and safe.

Machine equipped with infrared tool setting gauge, which can accurately adjust the cutting size and improve cutting quality. adopt high-precision linear guide rails, coordinate with high-precision helical gear transmission, ensures high precision cutting.

The core control components use international first-line brands, with stable performance and long service life. Machine body is welded by thick square tubes,And with heat treatment and vibration aging treatment, machine without deformation after used for a long time , which can maintain high cutting precision continuously.

Cutting machine install with closed dust-proof drag chain, all wires are installed in the drag chain. to isolate dust, water, oil, etc., so it can well prevent damage to the wires and prolong the service life of the machine.

Machine is compact and rational designed, saves workshop space, reduce installation work (no foundation required).

Product detail pictures:

Related Product Guide:

We have state-of-the-art equipment. Our products are exported for the USA, the UK and so on, enjoying a fantastic status among the clients for High Quality Block Cutting Machine - 4 AXIS BRIDGE CUTTING MACHINE – MACTOTEC , The product will supply to all over the world, such as: Bangladesh, Latvia, Romania, So We also continuously function. we, focuse on high quality, and are conscious of the importance of environmental protection, of the merchandise are pollution-free, environmentally friendly products, reuse on the solution. We've Updated our catalog, which introduces our organization. n detail and covers the primary items we provide at present, You may also visit our web-site, which involves our recent product line. We look forward to reactivating our company connection.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.