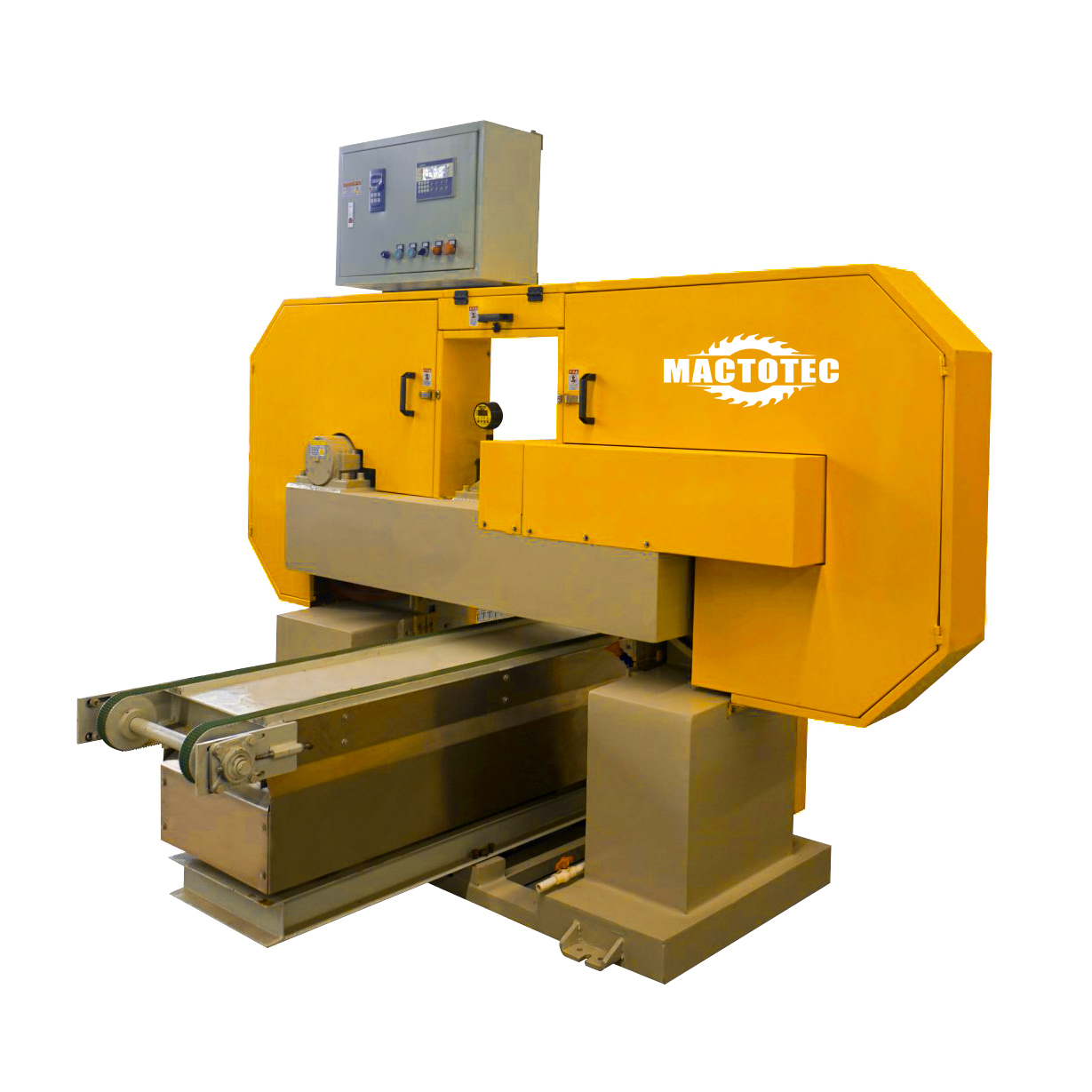

Fast delivery Stone Polishing Pads - Multi-function edge polishing machine – MACTOTEC

Fast delivery Stone Polishing Pads - Multi-function edge polishing machine – MACTOTEC Detail:

This machine is well designed for the grinding of beveling edge, flat edge, bottom 45 degrees beveling cut, skirting, and all other kinds of edges in different sizes and thicknesses. Works perfect on granite, marble, quartz and porcelain.

MTCSQ-14 Multi-function stone edge polishing machine equip with 14 polishing heads.5 heads for profiling edge, 5 heads for flat edge , 3 heads for 45 degrees beveling edge. 1 head install with blade for 45° beveling cut from bottom. rough grinding, fine grinding,being processed at one time. And it is multi-functional for all kinds of edges profiling and polishing.

Granite Edge polisher process thickness can be 8-80mm.

Grinding head up and down adjustable.

Strong motor provide machine with strong working power:

Profile edge 1# 2#( 4.5kw each) , 3# 4# 5# (3kw each).

Flat edge 6#(4.5kw each), 7# 8# 9# 10# (3kw each)

Beveling edge t 11# (3kw), 12#13#(2.2kw each)

Bottom 45 degrees beveling cut 14# (5.5kw)

High grade belt-type rubber fixture device, ensure accuracy and stable conveying of slab materials, greatly improve grinding performance and finished products quality.

Solid grinding head seat for professional mold opening. Ensures machine not vibrate (shock absorption) during the grinding process.

Automatic frequency conversion, different from the traditional stepless speed regulation, the speed can be freely and quickly adjusted, greatly facilitates the operation, and prolongs the service life of the motor.

The base and the beam of the granite&marble edge polishing machine are all cast iron parts, and are processed by high temperature annealing and precision grinding machines, with super quality and high precision.

When adjusting different processing thicknesses, it can be Refer to the digital display on the front beam for adjustment, which has the advantages of advanced structure, high precision, convenient operation .

Stone edge polishing machine volts/frequency can be customized as per required.

Skirting(all kinds of other edges)

Flat edge polishing

Beveling/flat edge polishing

“L” shaped slot

Technical Data

| Heads |

14 pcs |

| Minimum processing size |

60*60mm |

| Processing thickness |

8-80mm |

| Feeding speed |

0.7-5m/min |

| Total power |

47kw |

| Weight |

4800kgs |

| Dimension |

8800*1000*2000mm |

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for Fast delivery Stone Polishing Pads - Multi-function edge polishing machine – MACTOTEC , The product will supply to all over the world, such as: British, Melbourne, Holland, We have got constantly insisted on the evolution of solutions, spent good funds and human resource in technological upgrading, and facilitate production improvement, meeting the wants of prospects from all countries and regions.

We have been looking for a professional and responsible supplier, and now we find it.