Factory Supply Granite Polishing Pads - Edge profile & Polishing Machine – MACTOTEC

Factory Supply Granite Polishing Pads - Edge profile & Polishing Machine – MACTOTEC Detail:

INTRODUCTION

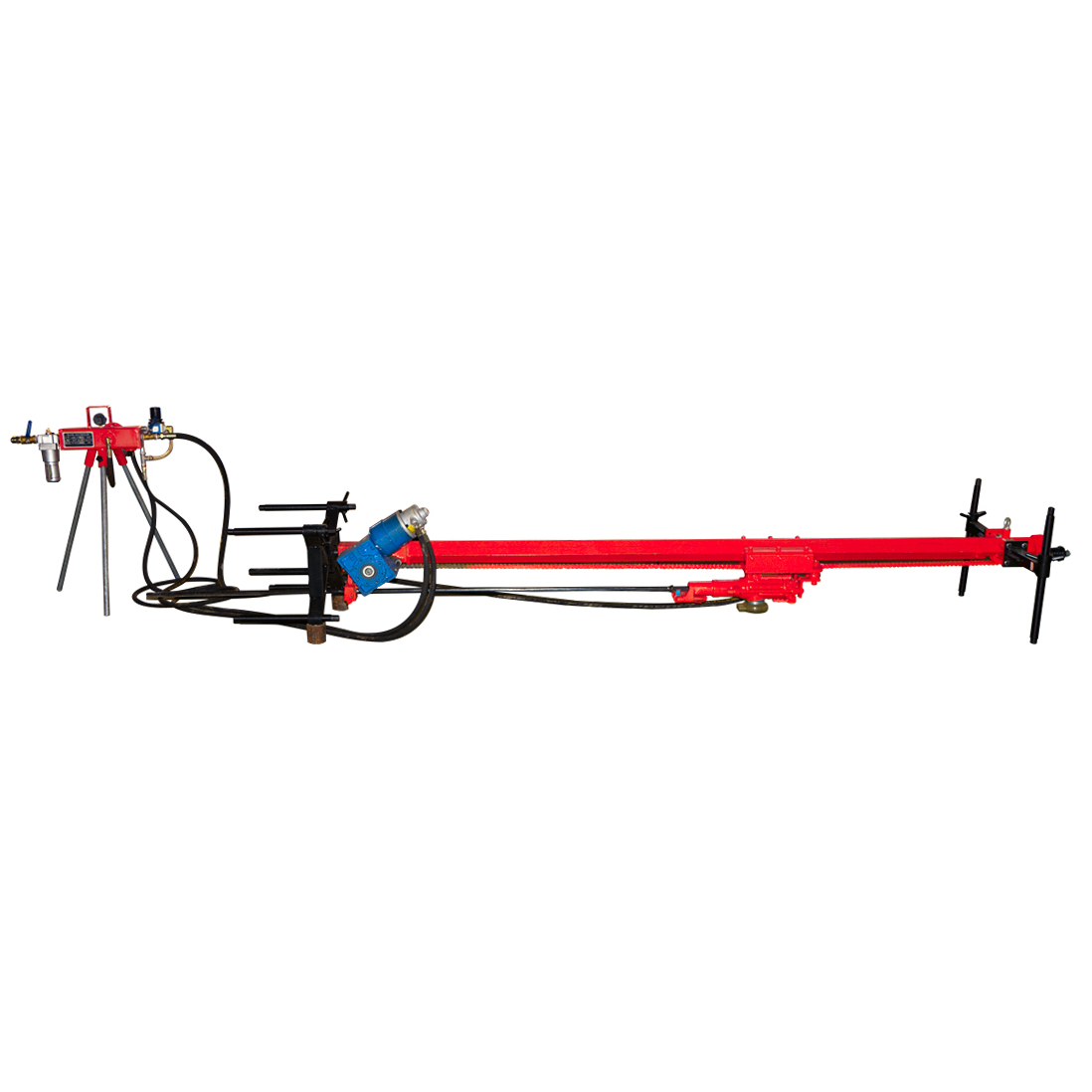

This machine is an economical machine for stone materials such as marble and granite edge processing . function of processing various straight edge, curve edge and inner hole edge.. The grinding head can rotate 90°, it ca also be replaced with saw blade which can be used for grooving and cutting.

By using the diamond wheels of corresponding shapes, it can process different edges such as the bullnose, half bullnose, ogee, flat and etc. The machine can do the linear edge automatically. it can also do the arc edge by holding the arm manually.

Different with automatic edge polisher, this machine moving is driven by gears which is stable and reliable. The rail is designed without wearing because it is closely emerged into oil and attached by steel band. The sliding board of machine is attached by anti-wearing board in order to decrease the mechanical vibration dramatically. Dual-speed motor adopted to bring faster polishing speed with higher finishing degree.

Double T type worktable makes it easy for slabs fixed when on processing.

Straight line grinding:

Straight-line grinding is relatively simple. The operator puts the slab material on the worktable, moves forward a certain distance, straightens the direction, and determines the size (set the distance of the travel switch). At this time, the grinding head has been installed with the desired shape selected grinding wheel in advance. and then adjust the lifting slide ,to make the grinding wheel align with the edge of the slab , start the machine, and then adjust the longitudinal slide to control the feed amount to achieve the best working performance.

Curve Grinding :

When grinding the inner and outer curves, first remove the two zigzag fixing bolts on the longitudinal slide plate. At this time, it is in a bending and moving state. When grinding the outer curve, the operator holds the grinding head with both hands and grinds along the curve material. the inner hole can be grind according to the method of grinding the outer edge.

In general, to grind a forming line (straight line or flower line), it needs to go through four processes: diamond wheel, rough grinding wheel, fine grinding wheel and polishing wheel. The grinding wheel cone shaft configured by this machine has the advantages of quick and convenient wheel changing.

5.5 kw and 7.5 kw main motor power for optional.

Frequency converter installed for driving speed adjustment for optional.

Product detail pictures:

Related Product Guide:

Our commission should be to provide our end users and clients with very excellent and aggressive portable digital products and solutions for Factory Supply Granite Polishing Pads - Edge profile & Polishing Machine – MACTOTEC , The product will supply to all over the world, such as: United Kingdom, Sudan, Benin, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We've been able to also provide you with no cost samples to meet your needs. efforts are going to be produced to supply you the very whole heartedly service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our items and enterprise. lot more, you'll be able to come to our factory to find out it. We'll constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should really feel absolutely free to make contact with us for small business and we believe we'll share great trading practical experience with all our merchants.

This company has the idea of better quality, lower processing costs, prices are more reasonable, so they have competitive product quality and price, that's the main reason we chose to cooperate.