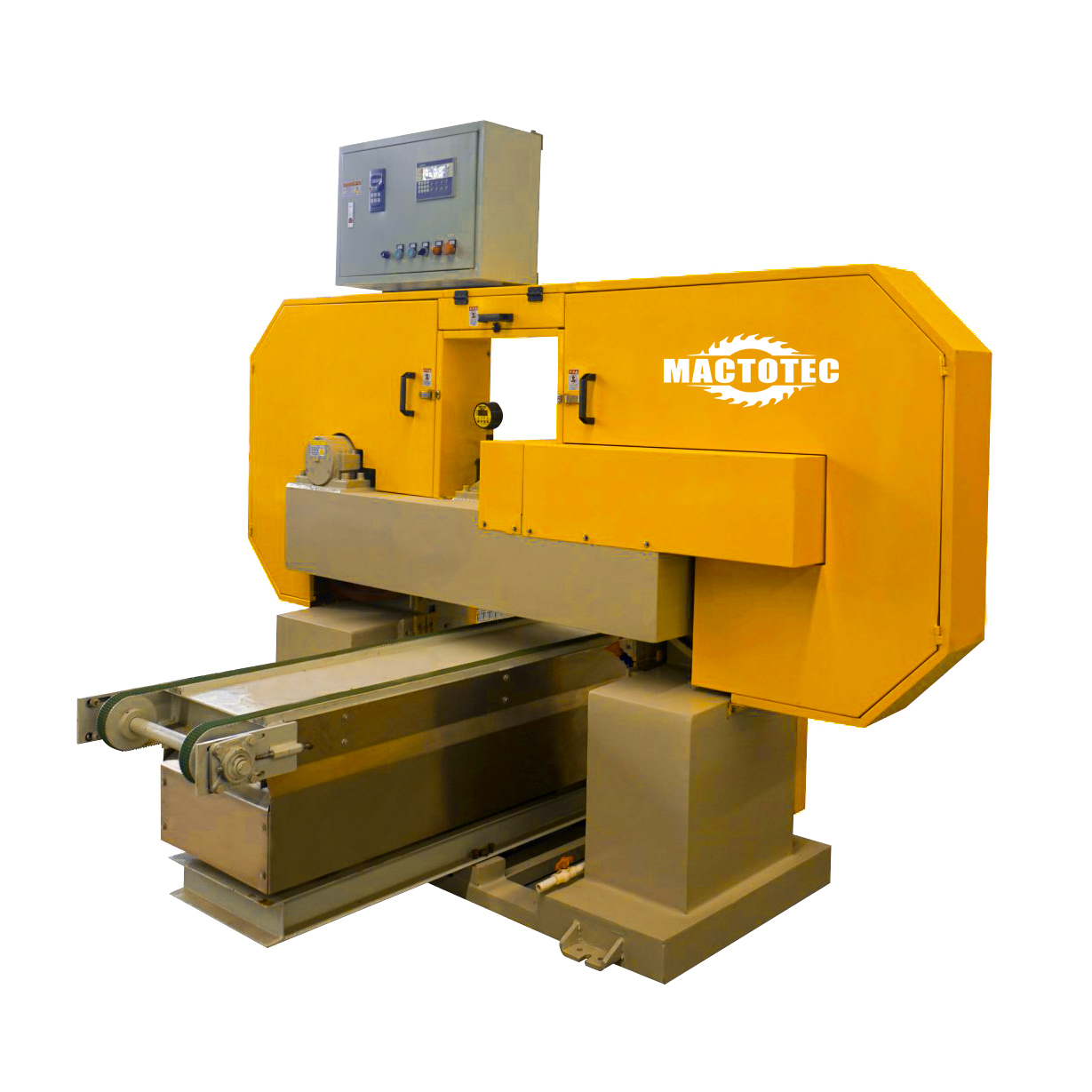

factory Outlets for Corner Stone Veneer Saws - STONE HORIZONTAL SLICING MACHINE – MACTOTEC

factory Outlets for Corner Stone Veneer Saws - STONE HORIZONTAL SLICING MACHINE – MACTOTEC Detail:

INTRODUCTION

This stone slicing machine is used to split the slab into half thickness or multi layers in horizontal, especially widely used for producing composited tiles.

Minimum slabs thickness after processed can reach 2mm.

Stone horizontal slicing Machine maximum thickness can be processed is 160mm.

Table feed slabs for slicing automatically and its speed is adjustable according to stone hardness.

The height of working table is less 140mm, so the loading and unloading stone is easy. It can save time and labor.

The saw belt adopts automatic constant hydraulic tension. with advantages of uniform and stable strength, prolong the service life of the saw belt, and makes operation more convenient.

The cutting parameters can be setted and adjusted by screen or buttons and controlled by PLC automatically, which makes operation very easy and improve the work efficiency greatly.

High quality steel material and electrical accessories adopted on machine, make ensure machine works well and decrease the future maintenance cost.

This stone horizontal splitting Machine can work stably in automatic mode, or manually with buttons.

Machine equip with automatic lubrication device. Convenient for maintenance during using of machine.

Production efficiency for this machine about 2-5㎡ per hour as per stone hardness.

Till now it has three types of this machine for your optional from MACTOTEC as per your actual producing demand:

Marble only ( Marble saw belt horizontal splitting machine type)

Granite only( Granite diamond horizontal splitting machine type )

Marble and Granite (Marble and granite double use horizontal splitting machine type).

For the working width, regular models available is 800mm and 1200mm, if you need any other width, please feel free to contact MACTOTEC , customize is acceptable.

Machine before shipped to customers will be carefully inspected and debugged by engineers, ,make sure machines received by customers can put into production with 100% satisfaction.

Machine warranty is 12 month after deliver.

Technical data

| Model |

|

MTWK-800 |

| Max. Processing Width |

mm |

850 |

| Travel Height |

mm |

80 |

| Max. Processing Thickness |

mm |

160 |

| Main Motor Power |

kW |

5.5 |

| Total Power |

kw |

6.5 |

| Voltage/Frequency |

V/Hz |

380/50 |

| Blade Length |

mm |

5950 |

| Blade Thickness |

mm |

2 |

| Water Consumption |

m3/h |

2 |

| Capacity |

m2/h |

3-5 |

| Overall Dimensions(L*W*H) |

mm |

2650*2300*2200 |

| Gross Weight |

kg |

1800 |

Technical data

| Model |

|

MTWK-1200 |

| Max. Processing Width |

mm |

1250 |

| Travel Height |

mm |

80 |

| Max. Processing Thickness |

mm |

160 |

| Main Motor Power |

kW |

7.5 |

| Total Power |

kw |

8.5 |

| Voltage/Frequency |

V/Hz |

380/50 |

| Blade Thickness |

mm |

2 |

| Water Consumption |

m3/h |

2 |

| Capacity |

m2/h |

3-5 |

| Overall Dimensions(L*W*H) |

mm |

4200*3100*2200 |

| Gross Weight |

kg |

2200 |

Product detail pictures:

Related Product Guide:

We've numerous great employees customers excellent at promoting, QC, and working with kinds of troublesome difficulty inside the generation method for factory Outlets for Corner Stone Veneer Saws - STONE HORIZONTAL SLICING MACHINE – MACTOTEC , The product will supply to all over the world, such as: Sri Lanka, Cancun, Bahamas, We supply professional service, prompt reply, timely delivery, excellent quality and lower price to our customers. Satisfaction and good credit to every customer is our priority. We focus on every detail of order processing for customers till they have received safe and sound products with good logistics service and economical cost. Depending on this, our products are sold very well in the countries in Africa, the Mid-East and Southeast Asia.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.