Factory Cheap Hot Marble Slab Polisher - AUTOMATIC STONE FLAT EDGE AND BEVELING EDGE POLISHING MACHINE – MACTOTEC

Factory Cheap Hot Marble Slab Polisher - AUTOMATIC STONE FLAT EDGE AND BEVELING EDGE POLISHING MACHINE – MACTOTEC Detail:

Vertical structure, makes slabs feeding and unload easy.

Cast iron girder, base and polishing head set, annealing treated, ensures machine of stable and durable quality, keeps longer lifetime.

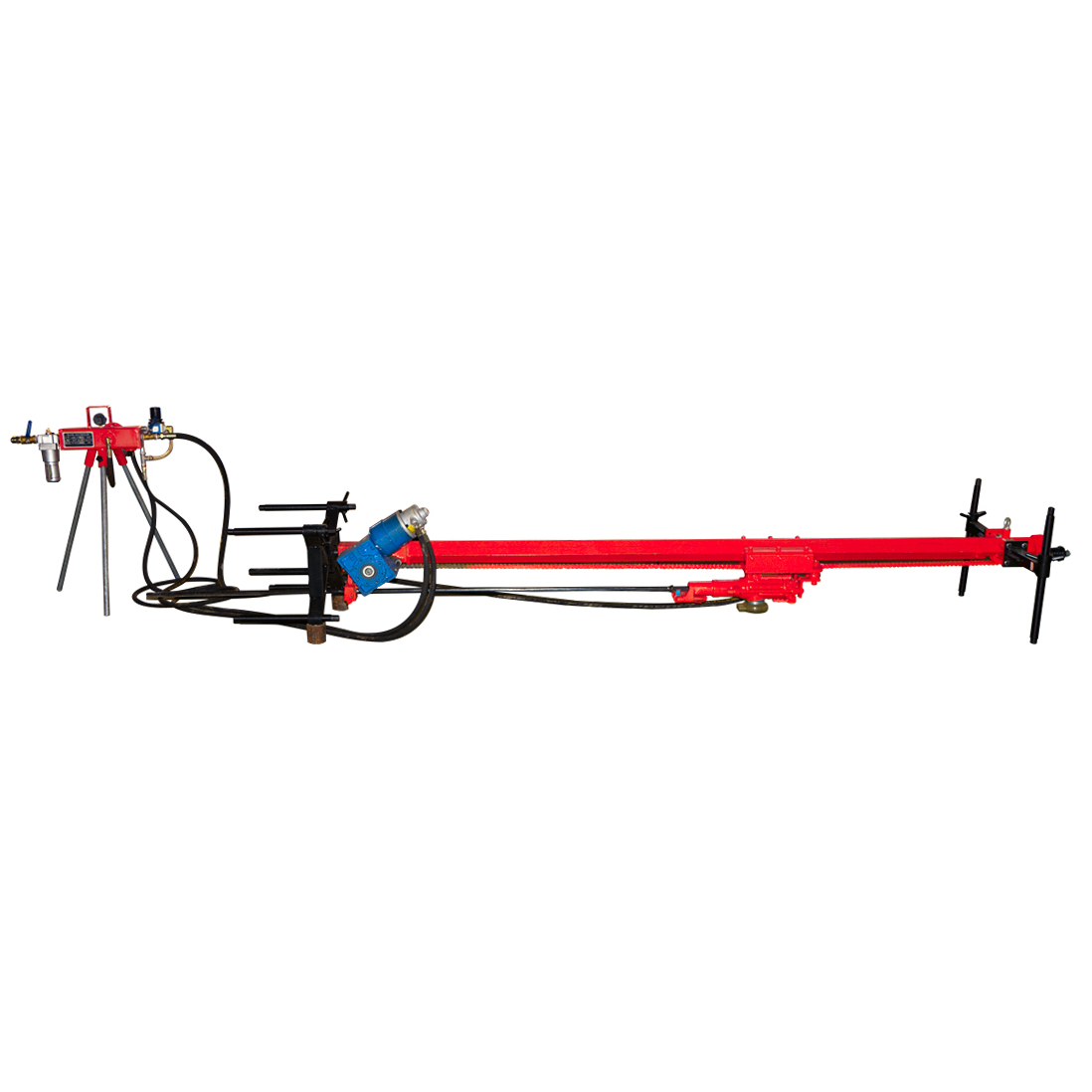

MTCSQ-11 Automatic stone flat edge and beveling edge polishing machine equip with 11 heads, 6 heads for flat edge , 4 heads for 45 degrees beveling edge. 1 head install with blade for 45°cut from bottom. rough grinding, fine grinding,flat edge and beveling edge polishing completely being processed at one time.

Edge polishing machine process thickness can be 8-80mm.

Grinding head up and down adjustable.

Strong motor power gives machines strong working force:

Flat edge 1#( 4.5kw) , 2# 3# 4# 5# 6# (3kw each).

Beveling edge 7#(3kw), 8# 9# 10# (2.2kw)

Bottom 45 degrees beveling cut 11# (5.5kw)

High grade belt-type rubber fixture device, ensure accuracy and stable conveying of slab materials, greatly improve grinding performance and finished products quality.

It adopts frequency conversion speed regulation, the speed can be freely and quickly adjusted for better deal with different thickness of slabs .

Each polishing head can be controlled independently, for example, if you only need do beveling edge polishing , you can turn off the control switches for the other heads. In this case can better satisfy the actual processing requirement.

When adjusting different thicknesses, you can refer to the front beam digital display meter, convenient and accurate.

Stone edge polisher volts/frequency can be customized as per required.

Every detail of each machine set are carefully inspected and debugged repeatedly before delivery to ensure that the product is shipped with “zero” defects.

Technical Data

| Model |

MTCSQ-11 |

|

| Heads Quantity |

pcs |

11 |

| Feeding Speed |

m/min |

0.7-5 |

| Min Processing Size |

mm |

100*100 |

| Processing Thickness |

mm |

3-60 |

| Total Power |

kw |

38 |

| Overall Dimension |

mm |

7800*1000*2500 |

| Weight |

kg |

3800 |

Product detail pictures:

Related Product Guide:

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Factory Cheap Hot Marble Slab Polisher - AUTOMATIC STONE FLAT EDGE AND BEVELING EDGE POLISHING MACHINE – MACTOTEC , The product will supply to all over the world, such as: Eindhoven, Denmark, Finland, With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. Quality, honesty and service is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.