Diamond Wire Saw For Granite Quarrying

Rubberized diamond wire saw, used for granite quarrying and granite block squaring, most frequently used are Φ11.5 mm with 38 beads and 40 beads/m.

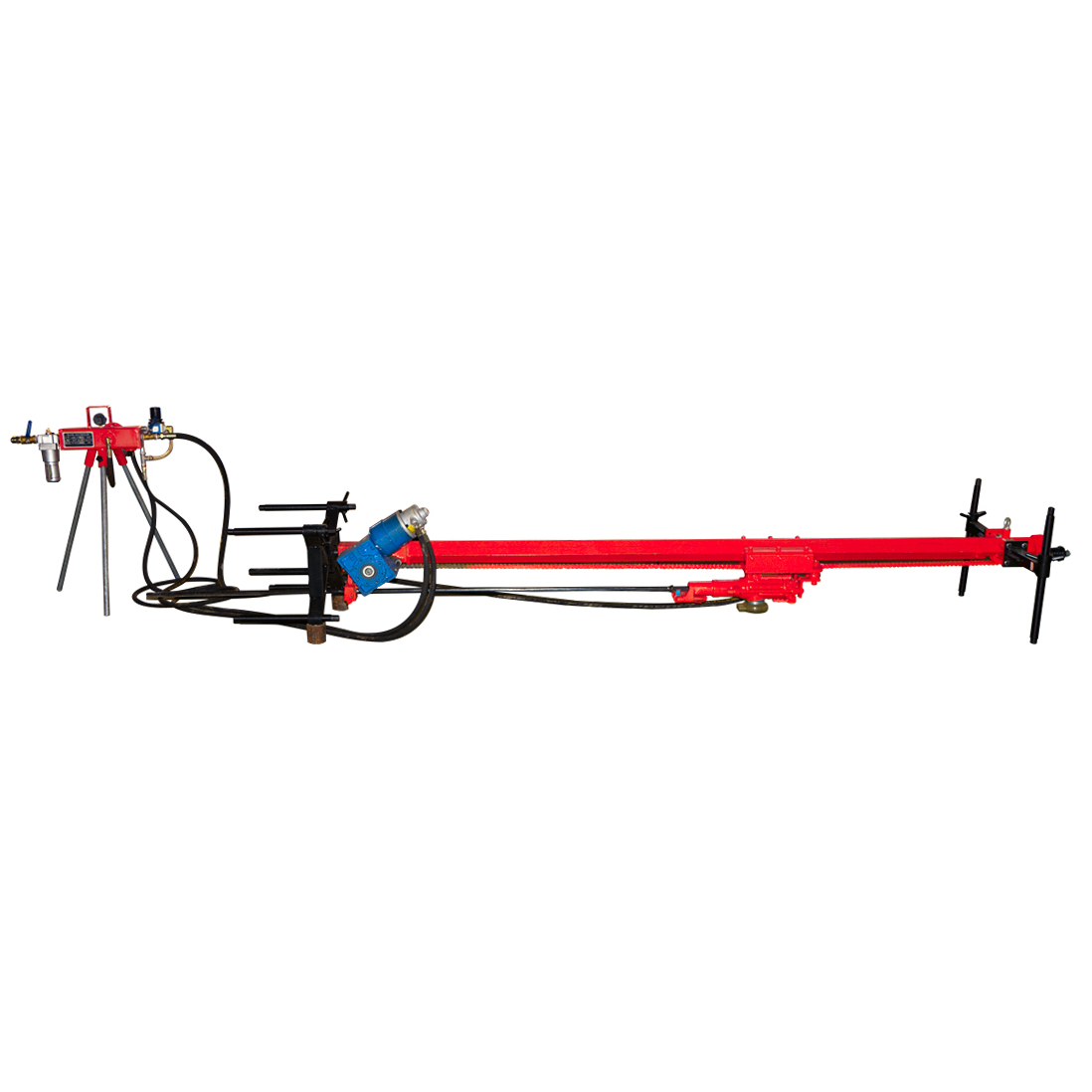

Cutting methods: Vertical, Horizontal, turn 90°direction, blind cutting.

11.5mm beads diamond wire saw cutting medium hard granite at Portugal

Features & Advantages

1.High efficiency, reliable cutting, high output, easy and safe working, environmental friendly.

2.High performance leads to perfectly shaped blocks without inner breaks.

3.Exploit the large dimension blocks.

4.The rubber and cable sticking together tightly make good bonding, and it can bear more strikes during the cutting.

5.Good temperature resistance, and it can be used when water is insufficient.

6.It can be used for smaller curvature radius.

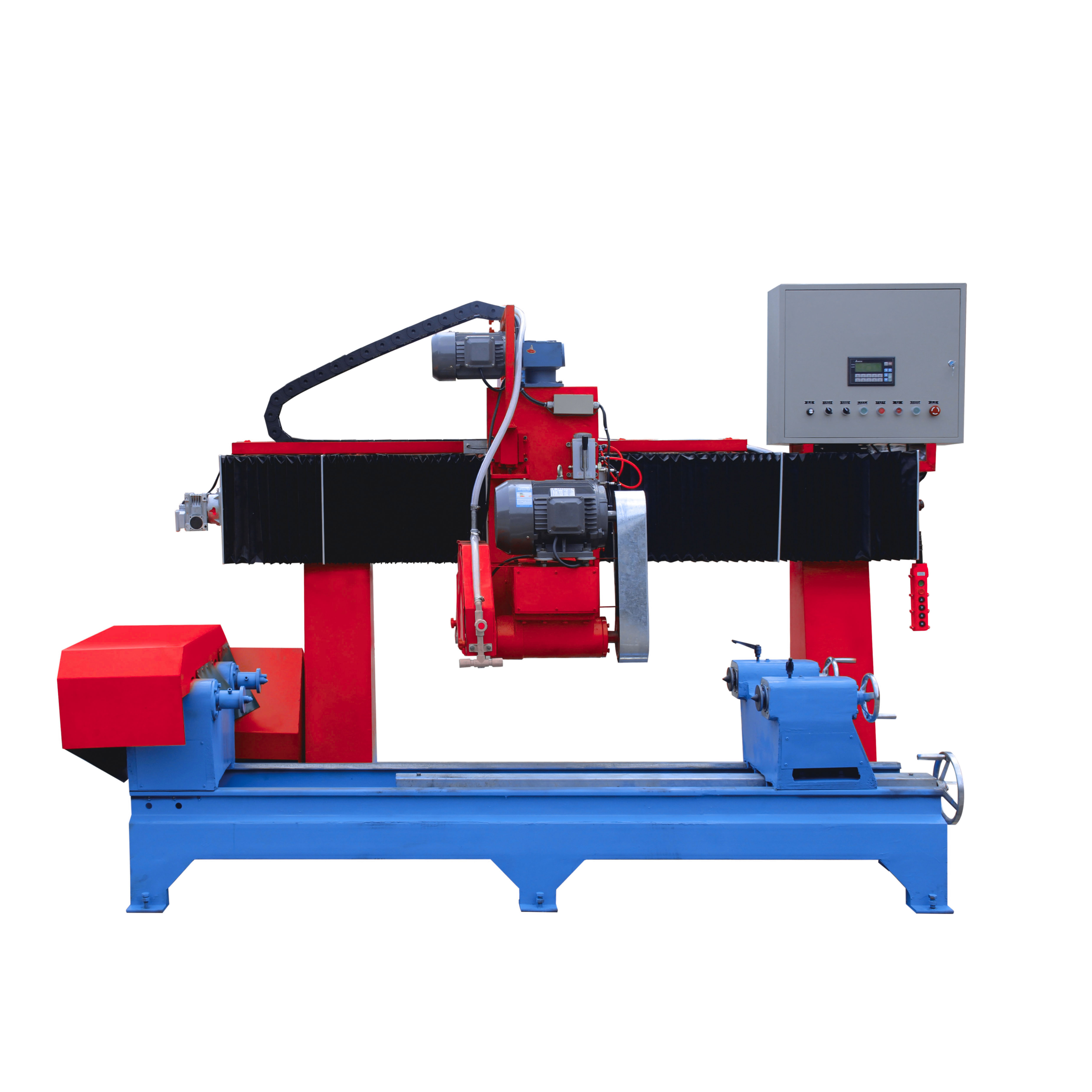

7.Used for wire saw machines with 37-110kw main power motor.

8.Cooling water flow range with 25-50L/min.

First stage cutting using 11.5mm diamond wire saw to cut a large surface at Finland

Specifications

| Bead dia.(mm) | Fixed by | Beads/M | Cutting Material | Line Speed(m/s) | Efficiency(m2/h) | Life time(m2/m) |

| Φ11mm Sintered beads | High performance Rubber | 37-42 | Soft granite | 22-28 | 8-10 | 20-22 |

| Medium hard granite | 20-24 | 6-8 | 18-20 | |||

| Φ11.5mm Sintered beads | Hard granite | 18-22 | 5-7 | 10-12 | ||

| High abrasiveness | 26-30 | 4-8 | 8-15 |

Accessories

11.5mm sintered beads

Connectors for joining wire saw into loops

Hydraulic press for pressing connectors

Scissors for cutting wire steel cord