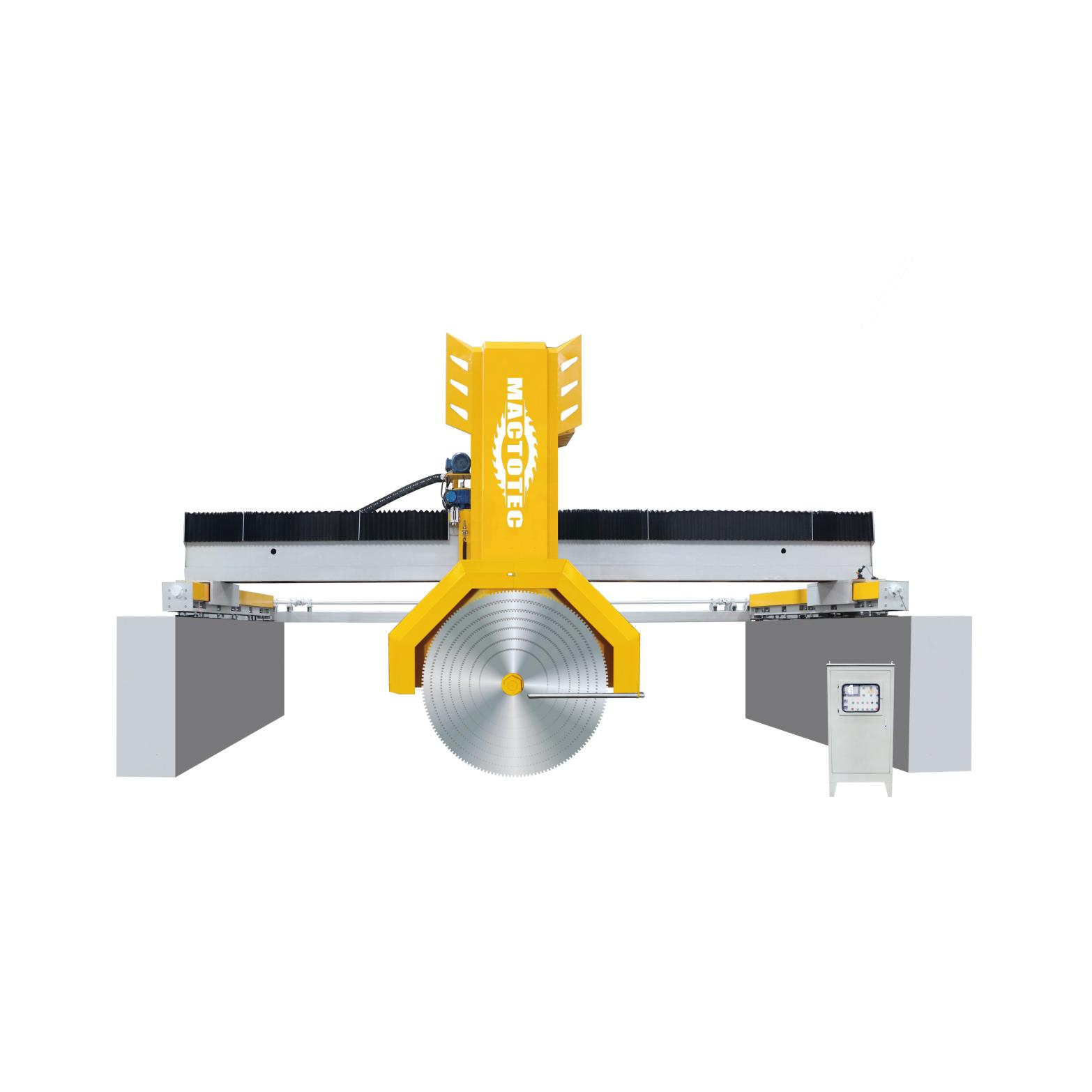

Bridge Type Block Cutting Machine for Granite and Marble

INTRODUCTION

Bridge type block cutting machine designed by bridge structure to ensures better cutting precision and flatness of final slabs . well works on high-value granite and marble blocks.

Machine can hang with multi blades for cutting simultaneously, greatly improve the cutting capacity, and reduce consumption. It is also flexible applicable for single blade cutting.

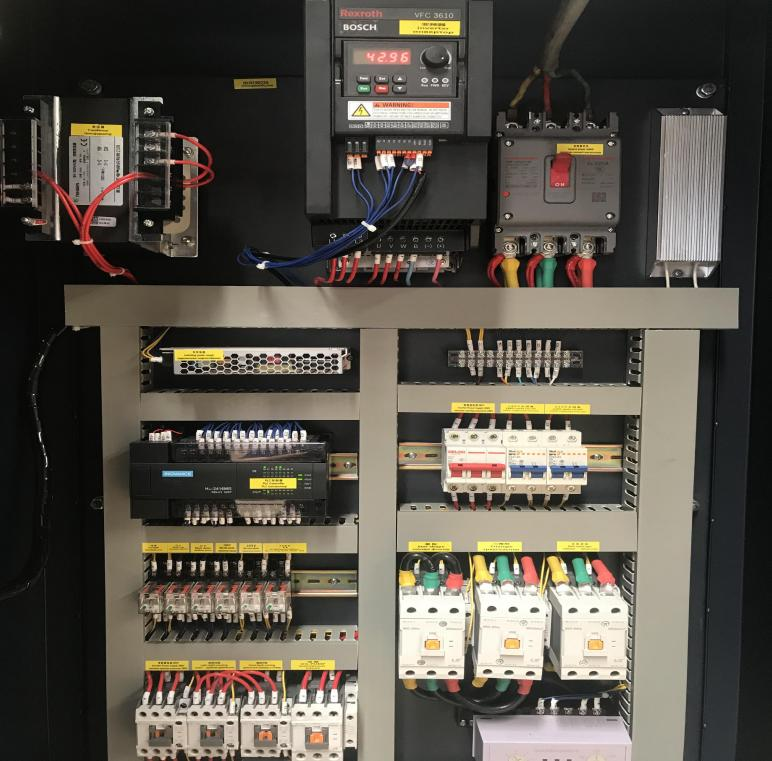

Block cutter adopts PLC programmable control and man-machine operation interface, supplemented by ultra-high-precision rotary encoder for slicing.

Block cutter left-right movement adopts frequency conversion controller, speed adjustable as per stone material actual characteristics. the up and down movement adopts four guide pillars hydraulic lifting system.

Granite and Marble block cutting machine adopts PLC programmable control and man-machine operation interface, touch screen adopts Chinese、English and Russian operation interface, easy operation and high efficiency cutting.

Machine adopt four guide columns with double hydraulic lifting structure, with high stability to ensure the machine safe operation. It adopts solid chrome-plated four guide column with smooth surface and rust resistance. mechanical parts are selected from standard grade castings, steel, and famous brand bearings with highest quality of materials, therefor the machine rigid is great and stable

The beam and side beams are cast as a whole,with good overall rigidity and strength, The beam and side beam adopt rack and pinion and v-shaped slide rail structure, with advantages of high precision, low failure rate and durable.The position of the transmission beam motor reducer is designed with waterproof offset printing to better protect the machine and extend the service life of the machine.

Stone Blocks can be placed directly on the ground,saving trolleys and maintenance costs, or you can choose a trolley or a rotary worktable according to the production process needs.

Stone cutting machine adopts import and domestic famous brand electric components. Such as the inverter is BOSCH; the switch button is SIEMENS; the relay and position switch is OMRON; the contactor is Japan FUJI; the main cable is from China first line brand. which is high quality、low failure rate and good stability.

The guide column lifting adopts hydraulic system. It is equipped with double oil cylinders, which runs smoothly and has strong overload protection.

Packing & Loading:

Technical Data

| Model |

MTSJ-2200 |

MTSJ-2500 |

MTSJ-2800 |

|

| Max. Blade Diameter |

mm |

Φ2200 |

Φ2500 |

Φ2800 |

| Disk quantity |

pc |

1-13 |

1-13 |

1-13 |

| Max. Processing Length |

mm |

3800 |

3800 |

3800 |

| Max. Processing Width |

mm |

2300 |

2300 |

2300 |

| Lifting Stroke |

mm |

1250 |

1250 |

1250 |

| Bridge Beam Size |

mm |

7500*500*600 |

7500*600*700 |

7500*650*750 |

| Side Beam Size |

mm |

4000 |

4000 |

4000 |

| Guide Pillar Diameter |

mm |

140 |

140 |

140 |

| Water Consumption |

m3/h |

15 |

15 |

15 |

| Main Motor Power |

kw |

45 |

45 |

55 |

| Dimension |

mm |

8000*4500*3700 |

8000*4500*3700 |

8000*4500*3900 |

| Weight |

kg |

13000 |

13500 |

14000 |