Automatic Stone Flaming Machine

INTRODUCTION

The stone flaming machine is to process the surface of granite with a centralized split torch to form the desired texture effect through mechanical form.

Slab surface burned with liquefied gas and oxygen through a high temperature flame. Due to the uneven expansion of heat, it forms a slightly uneven effect like a lychee surface, which has function of non-slip Granite flamed slabs can be used on sidewalks, highways, indoor floors and walls. it mainly used in municipal paving projects (such as sidewalks, squares, and community beautification). Fired surface can also be used as external drywall dry hanging.

The flaming machine for granite movement process is as follows: the granite slabs to be processed are transferred to the conveyor rack driven by the motor and driven by the chain driven rollers through lifting device (crane). First, spray and wash the slab with water, remove the ash and debris on the slab surface by brush, and dry it by blowing. Then, the slabs to be processed are transported to the flame jet combustion processing area for processing in a stepwise manner. The processed slab being washed, cooled, slag removed, blown and dried, and then transported to the unloading area through the integrated conveying device and transferred to the slate bracket by the lifting device crane.(lifting device- crane is optional).

The equipment using 40*80mm tube as a skeleton structure.

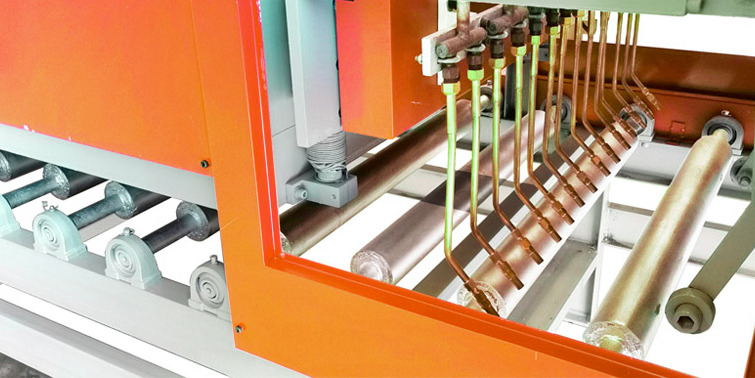

Slab transfer mechanism adopt rubber wheel, steel wheel alloy wheel with chain coupling drive to achieve constant continuous feeding.

Flaming machine with a roller brushes placed on exit of feeding, to better clean slab surface before processing and get a better processing performance.

Roller rack driving speed can be adjusted according to characteristics of slabs for flaming.

Flaming head left and right walking mechanism controlled and driven by frequency converter, speed can be adjusted through button, flaming head falling and drop mechanism is consists of listing motor and reducer lifting mechanism, its function is to get the best performance by adjusting the flaming head height according to slab variety and thickness .

Cooling system to cooling the slab which has been flamed to avoid fire-crack.

This automatic stone flaming machine with good performance on processing capacity of about 150square meters per hour .

Customers can choose different size of machine models to flame different width of stone materials such as 600mm, 800mm, 1000mm as your precise processing requirement, other width can be customized by MACTOTEC also.

Technical Data

| Model |

|

MTXL-600 |

MTXL-800 |

MTXL-1000 |

| Processing Width |

mm |

600 |

800 |

1000 |

| Number Of Nozzles |

pcs |

10 |

14 |

16 |

| Min. Processing Thickness |

mm |

15 |

15 |

15 |

| Max. Processing Thickness |

mm |

150 |

150 |

150 |

| Dust Removing Motor Power |

kw |

2.2 |

2.2 |

2.2 |

| Driving Motor Power |

kw |

1.5 |

1.5 |

1.5 |

| Lifting Motor Power |

kw |

0.37 |

0.37 |

0.37 |

| Swing Motor Power |

kw |

0.37 |

0.37 |

0.37 |

| Brush Motor Power |

kw |

0.55 |

0.55 |

0.55 |

| Capacity |

m2/h |

100-120 |

120-140 |

150-170 |

| Overall Dimensions |

mm |

9000*1200*1700 |

9000*1400*1700 |

9000*1800*1700 |

| Weight |

kg |

1000 |

1200 |

1400 |