Automatic Polishing Machine Line for Marble

INTRODUCTION

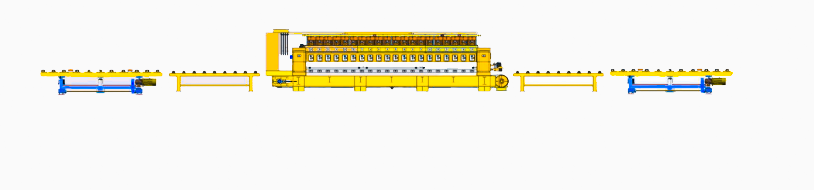

This automatic polishing machine is designed for grinding and polishing Marble slabs surface .

With 10/12/16/20/24 polishing heads available.

Marble polishing machine adopts Italy advancing design and automatic controlling system. It is a new integration model of high-efficiency, low cost,easy operation and durable.

The unprocessed slabs enter into flat transmission belt by roller trolleys, the flat transmission belt then bring slabs under rotating polishing heads, the unprocessed slabs will become to the finished slabs through polishing process of these rotating heads, during the polishing, the bridge swings forward and backward, the rotating direction are opposite between every two polishing heads, According to the different requirements for polished degree, can adjust the slab transmission belt speed and the bridge swing speed by transducers, to reach the best required performance.

Marble Polisher adopts PLC terminal control system, The operators can set the parameter freely by the programmable controller with LCD screen.

The driving system is on the upper half position, which will be better protect to get rid of dust..

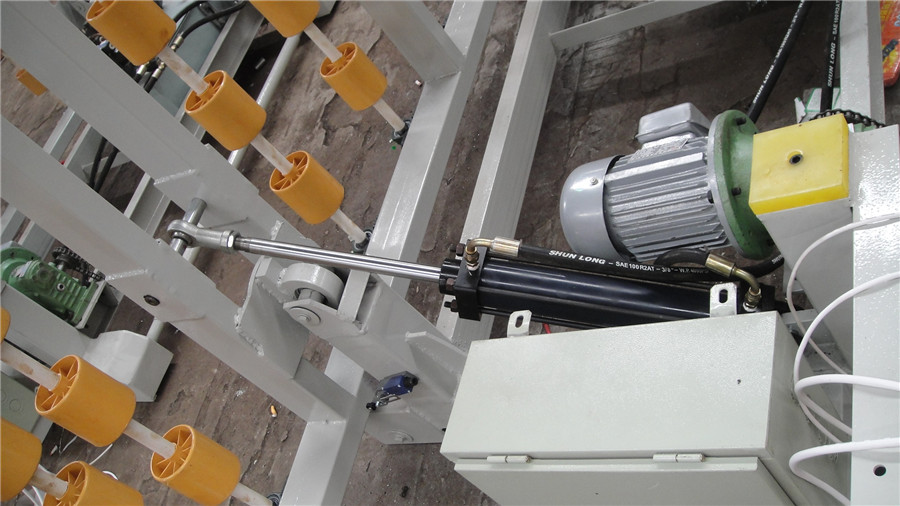

It equips with fault indicating system and alarming system abrasive consumption. to check and judge the abrasive wearing condition by adjusting the cylinder magnetic switch position on the top of polish heads. When the abrasive reduced to the limited position,it will send abrasive-lack alarm signals.

The conveyor belt and the cross beam adopt frequency conversions for speed adjusting. Its processing width and working pressure of grinding heads can be adjusted freely,

Stone polishing machine can identify the shape of slabs automatically, There is automatic recognition system for slab shapes on the slab entering parts, the automatic control system will deal with the signals which detected from the sensors and judge the shapes on processing, thus to make sure correct and effective up and down for polishing heads。

Polishing machine for marble is a heavy duty machine uses super quality grade casting iron and steel, brand-named electronic appliances, bearings and other components.

PLC:MITSUBISHI

Converter: SCHNEIDER

Contactor: Fuji

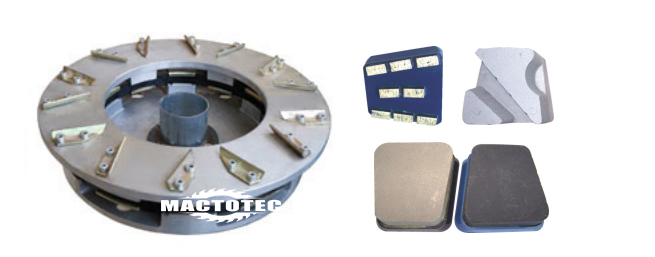

(Frankfurt Head for Marble width 1250mm)

Technical data

| Model |

|

MTWY-M12-1250 |

MTWY-M16-1250 |

MTWY-M20-1250 |

MTWY-M24-1250 |

| Qty. of polishing Heads |

pcs |

12 |

16 |

20 |

24 |

| Max. slab Width |

mm |

1250 |

1250 |

1250 |

1250 |

| Beam Swing Speed |

m/min |

3-35 |

3-35 |

3-35 |

3-35 |

| Driving Motor Power of Beam |

kw |

6 |

6 |

6 |

6 |

| Belt Transfer Speed |

m/min |

0.5~4.0 |

0.5~4.0 |

0.5~4.0 |

0.5~4.0 |

| Belt Transfer Motor Power |

kw |

3 |

3 |

3 |

3 |

| Pressure of Cooling Water |

mpa |

0.1-0.15 |

0.1-0.15 |

0.1-0.15 |

0.1-0.15 |

| Pressure Force of Compressor |

mpa |

0.7 |

0.7 |

0.7 |

0.7 |

| Main Motor Power |

kw |

9~11*12 pcs |

9~11*16 pcs |

9~11*20 pcs |

9~11*24 pcs |

| Water Consumption |

m³/h |

15 |

20 |

24 |

30 |

(Frankfurt Head for Marble width 2000mm)

Technical data

| Model |

|

MTWY-M10-2000 |

MTWY-M12-2000 |

MTWY-M16-2000 |

MTWY-M20-2000 |

| Qty. of Polishing Heads |

pcs |

10 |

12 |

16 |

20 |

| Max. Slab Width |

mm |

2000 |

2000 |

2000 |

2000 |

| Beam Swing Speed |

m/min |

3-35 |

3-35 |

3-35 |

3-35 |

| Driving Motor Power of Beam |

kw |

6 |

6 |

6 |

6 |

| Belt Transfer Speed |

m/min |

0.5~4.0 |

0.5~4.0 |

0.5~4.0 |

0.5~4.0 |

| Belt Transfer Motor Power |

kw |

3 |

3 |

3 |

3 |

| Pressure of Cooling Water |

mpa |

0.1-0.15 |

0.1-0.15 |

0.1-0.15 |

0.1-0.15 |

| Pressure Force of Compressor |

mpa |

0.7 |

0.7 |

0.7 |

0.7 |

| Main Motor Power |

kw |

15*10 pcs |

15*12 pcs |

15*16 pcs |

15*20 pcs |

| Water Consumption |

m³/h |

8 |

10 |

15 |

20 |