Automatic Polishing Machine Line for Granite

INTRODUCTION

This automatic polishing machine is well used for continuous grinding and polishing granite slabs surface .

With advantage of low labor intensity, high production efficiency, high processing accuracy and stable quality .

Granite polishing machine with 12/16/20/24 polishing heads optional, and with working width 1250mm /2000mm optional.

1250mm working width model uses resin disk head.

2000mm working width usually uses fickert 7 claws polishing head, brings super high processing capacity and fantastic finishing performance on granite material.

The automatic stone polisher is soundest choice to produce absolutely unprecedented gloss levels of slabs. Featured with high productivity, top quality and operation ease .

It radically solves the problem of polishing shade along the edges of slabs.

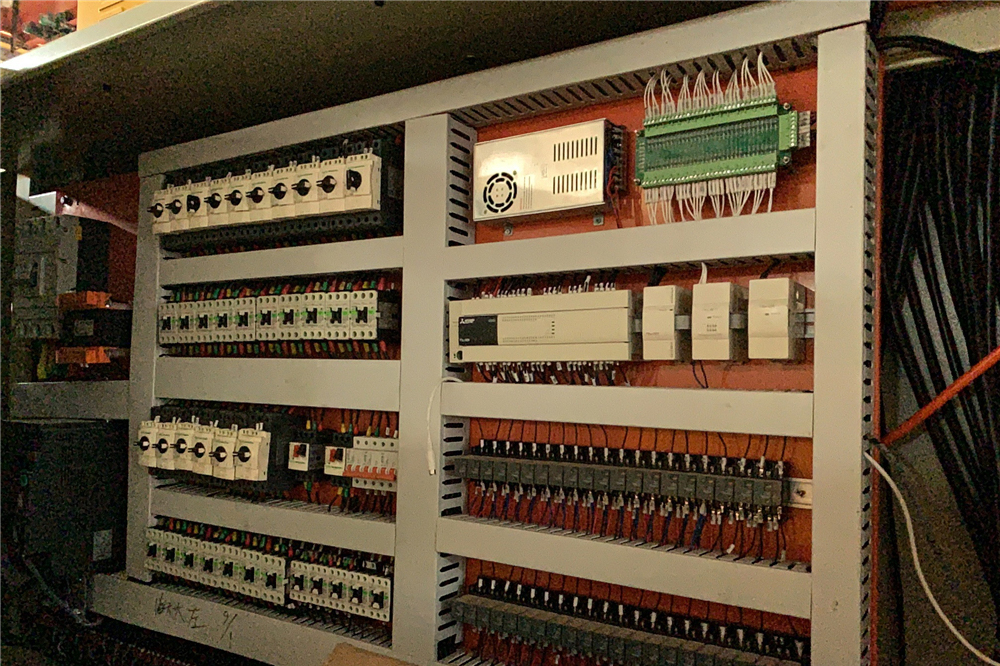

Machine adopts PLC control system, polishing parameters can be setted freely by the programmable controller with screen as per actual processing requirement..

Machine equipped with clever spindle assembly oscillating system, swing motion, interpolated with that of the beam, follows curved work paths that maybe configured as desired, to get a consistent quality finish on whole slab surface,

With Sensor at the machine entrance of slab which can detect the shape of the slabs in sequence and transmit the signal to controlling unit for precise working.

Brush system placed at slab exit of machine, automatically clean the polished slab surface .to keep a good final products appearance.

Automatic lubrication system adopted on machine, ,ensure moving parts and bearings well lubricated and prolong lifetime.

Frequency conversions device equipped on conveyor belt and the cross beam ,working speed can be adjusted according to actual stone characteristics.

Machine build with super quality grade casting iron and steel, brand-name electronic appliances and components , such as MITSUBISHI PLC, SCHNEIDER Converter, NSK bearing. Etc.

Whole line includes polishing machine, loading table, conveyor roller table, unloading table, dryer, compressor , air tank,etc as a standard supply.

(Resin Disk Head for Granite width 1250mm )

Technical Data

| Model |

MTWY-G12-1250 |

MTWY-G16-1250 |

MTWY-G20-1250 |

MTWY-G24-1250 |

|

| Qty. of Polishing Heads |

pcs |

12 |

16 |

20 |

24 |

| Max. Slab Width |

mm |

1250 |

1250 |

1250 |

1250 |

| Beam Swing Speed |

m/min |

3-35 |

3-35 |

3-35 |

3-35 |

| Driving Motor Power of Beam |

kw |

4.4 |

4.4 |

6 |

6 |

| Belt Transfer Speed |

m/min |

0.5-4.0 |

0.5-4.0 |

0.5-4.0 |

0.5-4.0 |

| Belt Transfer Motor Power |

kw |

2.2 |

2.2 |

3 |

3 |

| Pressure of Cooling Water |

mpa |

0.1-0.15 |

0.1-0.15 |

0.1-0.15 |

0.1-0.15 |

| Pressure Force of Compressor |

mpa |

0.7 |

0.7 |

0.7 |

0.7 |

| Main Motor Power |

kw |

7.5*12 pcs |

7.5*16 pcs |

7.5*20 pcs |

7.5*24 pcs |

| Water Consumption |

m³/h |

8 |

10 |

15 |

24 |

(Fickert Head for Granite width 2000mm )

Technical Data

|

Model |

|

MTWY-G12-2000 |

MTWY-G16-2000 |

MTWY-G20-2000 |

|

Qty. of Polishing Heads |

pcs |

12 |

16 |

20 |

|

Max. Slab Width |

mm |

2000 |

2000 |

2000 |

|

Beam Swing Speed |

m/min |

3-35 |

3-35 |

3-35 |

|

Driving Motor Power of Beam |

kw |

6 |

8 |

8 |

|

Belt Transfer Speed |

m/min |

0.5~4.0 |

0.5~4.0 |

0.5~4.0 |

|

Belt Transfer Motor Power |

kw |

3 |

4 |

4 |

|

Pressure of Cooling Water |

mpa |

0.1-0.15 |

0.1-0.15 |

0.1-0.15 |

|

Pressure Force of Compressor |

mpa |

0.7 |

0.7 |

0.7 |

|

Main Motor Power |

kw |

15*12 pcs |

15*16 pcs |

15*20 pcs |

|

Water Consumption |

m³/h |

15 |

20 |

25 |